Product lifecycle management is the management of all data and processes that are tied to the product record—from concept through design, development, and production. Product lifecycle management enables manufacturers and their supply chain partners to streamline product development and drive continuous improvement.

A product’s lifecycle typically begins with a concept or idea that stems from the identification of a new market opportunity. Feasibility studies are conducted early on to determine if the product is manufacturable from technical, regulatory, and financial standpoints. If the product is deemed feasible, the remaining processes associated with new product development (NPD) take place.

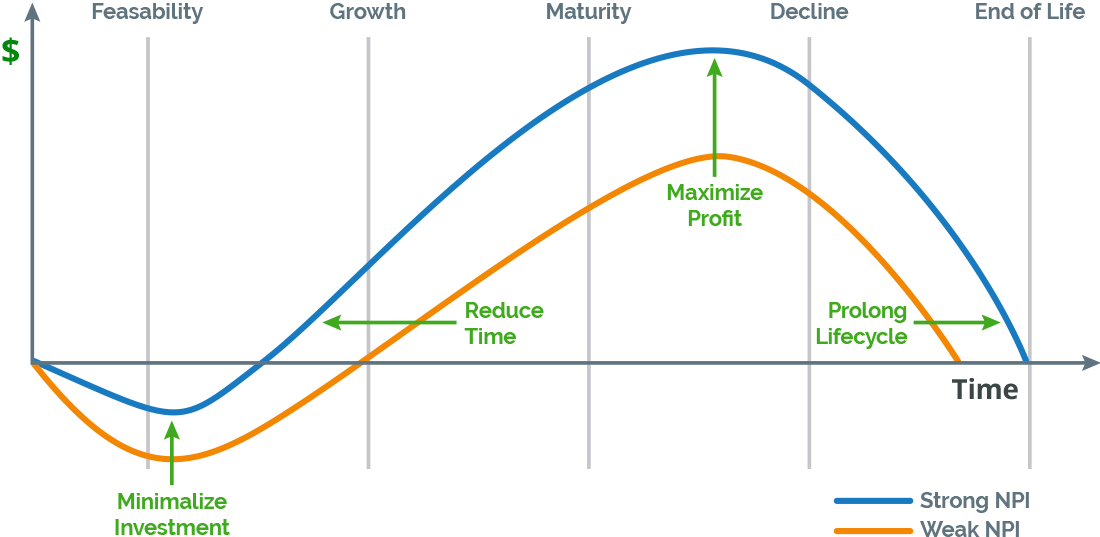

Upon completing NPD, the four key stages of the product lifecycle, including new product introduction (NPI), begin .

The Four Product Lifecycle Stages:

Here is why you need product lifecycle management.

PDM software provides a shared data repository for engineering workgroups to collaborate and manage design iterations.

PLM software systems, however, extend beyond the design phase to manage all data and drive all processes associated with new product development and introduction (NPDI).

Everyone on the team—not just engineering—can review the entire design and provide input before releasing the final product to production.

Product lifecycle management software provides a controlled and automated way to manage product and quality processes throughout the entire product lifecycle. It brings mechanical, electrical, and software designs into one shared platform—enabling dispersed teams to collaborate on the entire design before passing the released product to downstream systems.

Software-as-a-service (SaaS) PLM software speeds digital transformation by further eliminating collaboration latency, data errors, and security issues with a persistent digital thread that leads to faster product launches.

The bill of materials (BOM), which includes the entire assembly and all associated components, files, drawings, and specifications required to build a shippable product, is aggregated into a single shared system. This enables product teams and supply chain partners to create, import, share, change, compare, and approve product designs throughout the entire lifecycle. Check out our free BOM template here.

The bill of materials (BOM), which includes the entire assembly and all associated components, files, drawings, and specifications required to build a shippable product, is aggregated into a single shared system.

This enables product teams and supply chain partners to create, import, share, change, compare, and approve product designs throughout the entire lifecycle.

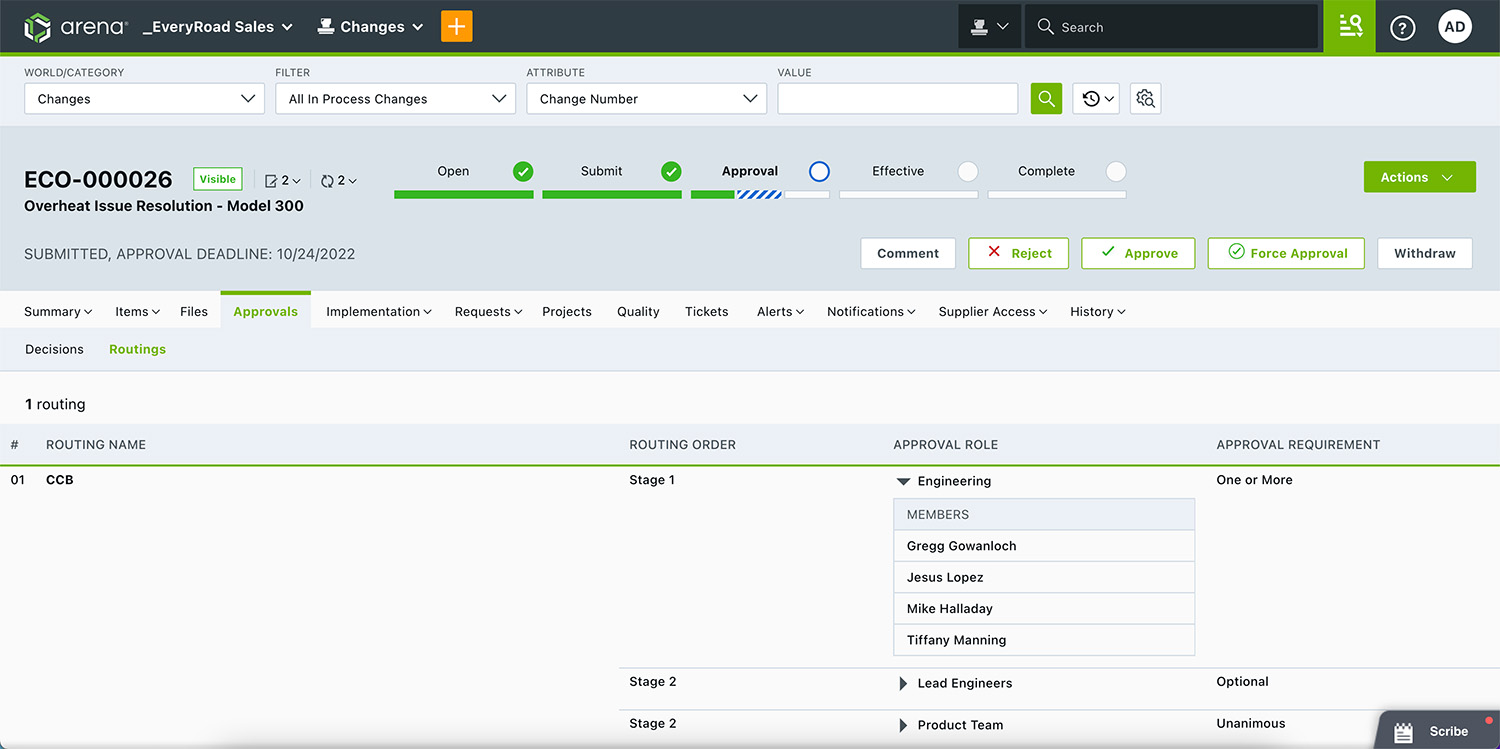

Automated engineering change order (ECO) processes enable internal teams and supply chains to review and approve changes rapidly anytime and anywhere. Check out our free ECO template here.

Required tasks and assignments are electronically tracked and linked to the appropriate part of the product record. This ensures product team members are always aware of key action items and deliverables.

Product lifecycle management software serves a wide range of industries—from high-tech electronics and clean tech to medical device, aerospace, and defense. As engineering, quality, procurement, and manufacturing teams work to develop and launch new products—product lifecycle management software provides a way to keep everyone aligned at all times, regardless of where teams and suppliers are located.

Whether you’re a small startup or Fortune 500 company, product lifecycle management software addresses the common challenges facing most manufacturers today:

Explore how companies are adopting product lifecycle management software to boost productivity, reduce costs, mitigate supply chain risks, and accelerate time to market (TTM).

The ability to effectively manage your bill of materials (BOM) ensures that the most current product revisions are accessed by all members of the product team, including supply chain partners. It also ensures that costs are properly allocated throughout the production phase and that product teams have visibility into any changes that may impact production further down the line.

Engineering change management provides controlled design change processes that speed product development. Product team members can process formal engineering change requests (ECRs) and engineering change orders (ECOs) more efficiently with automated approval routings. Team members can also document changes as they are released and track the status of change orders throughout the entire product lifecycle.

To meet the demands of today’s highly regulated environment, companies must be able to store, track, and manage all of the documentation associated with product and quality records. This includes product specifications, assembly instructions, standard operating procedures (SOPs), quality policies, and training records. Document management allows for the centralized storage of documentation, as well as the establishment of revision control and audit trails.

Project management capabilities allow the product team to keep track of tasks, assignments, and resources throughout the entire product lifecycle to ensure that all product development milestones are met.

The ability to link requirements to the product record enables organizations to manage and track issues, defects, and customer needs throughout the entire lifecycle and innovate more rapidly.

The ability to track and analyze metrics provides organizations greater insight into their product and quality processes to drive continuous quality improvement. Having access to key performance indicators (KPIs) also helps organizations take a more proactive stance in mitigating risks that may negatively impact NPDI.

In conjunction with product lifecycle management, many organizations rely on upstream and downstream software solutions to help manage the design and production phases of the product lifecycle. By connecting PLM software with these other systems, companies can further streamline their product development process and accelerate time to market (TTM).

Product lifecycle management software should allow for easy integration with these types of systems:

How Enterprise Cloud PLM Solutions Accelerate Return on Investment

Cloud-based enterprise PLM solutions drive efficiencies throughout the entire product lifecycle, enabling companies to accelerate the introduction of new, innovative products and gain a competitive advantage.

Unlike traditional on-premises PLM solutions which require costly IT resources and expenditures for hardware, software, virtual private networks (VPNs), and other related items—cloud-based platforms are managed by the PLM vendor. This eliminates infrastructure-related expenses and ongoing maintenance, thereby reducing your total cost of ownership (TCO).

Today, many Cloud PLM solutions are sold under software-as-a-service (SaaS) models which reduce long-term capital expenses with a pay-as-you-go subscription. This provides businesses a quicker payback period on their investment.

The ability to effectively manage your bill of materials (BOM) ensures that the most current product revisions are accessed by all members of the product team, including supply chain partners. It also ensures that costs are properly allocated throughout the production phase and that product teams have visibility into any changes that may impact production further down the line.

Engineering change management provides controlled design change processes that speed product development. Product team members can process formal engineering change requests (ECRs) and engineering change orders (ECOs) more efficiently with automated approval routings. Team members can also document changes as they are released and track the status of change orders throughout the entire product lifecycle.

To meet the demands of today’s highly regulated environment, companies must be able to store, track, and manage all of the documentation associated with product and quality records. This includes product specifications, assembly instructions, standard operating procedures (SOPs), quality policies, and training records. Document management allows for the centralized storage of documentation, as well as the establishment of revision control and audit trails.

Project management capabilities allow the product team to keep track of tasks, assignments, and resources throughout the entire product lifecycle to ensure that all product development milestones are met.

The ability to link requirements to the product record enables organizations to manage and track issues, defects, and customer needs throughout the entire lifecycle and innovate more rapidly.

The ability to track and analyze metrics provides organizations greater insight into their product and quality processes to drive continuous quality improvement. Having access to key performance indicators (KPIs) also helps organizations take a more proactive stance in mitigating risks that may negatively impact NPDI.

In conjunction with PLM, many organizations rely on upstream and downstream software solutions to help manage the design and production phases of the product lifecycle. By connecting PLM software with these other systems, companies can further streamline their product development process and accelerate time to market (TTM).

PLM software should allow for easy integration with these types of systems:

How Enterprise Cloud PLM Solutions Accelerate Return on Investment

Cloud-based enterprise PLM solutions drive efficiencies throughout the entire product lifecycle, enabling companies to accelerate the introduction of new, innovative products and gain a competitive advantage.

Unlike traditional on-premises PLM solutions which require costly IT resources and expenditures for hardware, software, virtual private networks (VPNs), and other related items—cloud-based platforms are managed by the PLM vendor. This eliminates infrastructure-related expenses and ongoing maintenance, thereby reducing your total cost of ownership (TCO).

Today, many Cloud PLM solutions are sold under software-as-a-service (SaaS) models which reduce long-term capital expenses with a pay-as-you-go subscription. This provides businesses a quicker payback period on their investment.

Click on each benefit below to see how Cloud PLM solutions help drive results.

Consider these key factors when evaluating what it takes to implement a PLM software solution successfully.