How to Avoid Million-Dollar Mistakes When Selecting Alternative Parts

Inside This Article

Product teams face mounting pressure to source reliable electronic components amid today’s unpredictable supply chain landscape. One wrong part can stall a launch, drain budgets, and haunt your engineering team for years—and if you’ve ever experienced the fallout from a costly part selection mistake, you know the stakes are high.

Arena Senior Customer Success Coach Marshall Wood knows firsthand how tough supply chain management can be. As a seasoned product lifecycle management (PLM) expert, he’s helped hundreds of companies in industries like high-tech and aerospace and defense navigate these challenges with confidence.

We recently sat down with Marshall to discuss how manufacturers can better manage alternative parts sourcing and mitigate risks using modern solutions like Arena Supply Chain Intelligence (SCI).

What Are Some of the Biggest Obstacles Product Teams Face With Sourcing and Supply Chain Reliability?

Marshall: The biggest issue is unpredictability. Supply chains are vulnerable to political shifts, economic instability, and natural disasters. These disruptions result in longer lead times, higher costs, and limited availability.

Regulatory compliance adds another layer of complexity. Teams must ensure suppliers adhere to regulations like RoHS, REACH, and conflict minerals. And it’s not a one-time check—ongoing audits and supplier reviews are critical to maintaining consistency.

Beyond Form-Fit-Function (FFF) Rules, What Should Teams Consider When Selecting Alternative Electronic Components?

Marshall: Regulatory compliance is huge. Two parts might be functionally identical, but if they’re made with different materials, one might not meet certain compliance standards. Country of origin also matters; political or environmental instability in a region can affect lead times and costs. You need to evaluate these factors before approving an alternative.

When in the Product Lifecycle Should Engineering Teams Start Thinking About Alternative Parts?

Marshall: As early as possible. Identifying long lead-time or high-cost items upfront helps shape the product delivery schedule. It enables teams to adjust designs or sourcing strategies to avoid delays and cost overruns.

How Difficult Was It to Verify Alternative Parts Before Solutions Like Arena SCI Were Available?

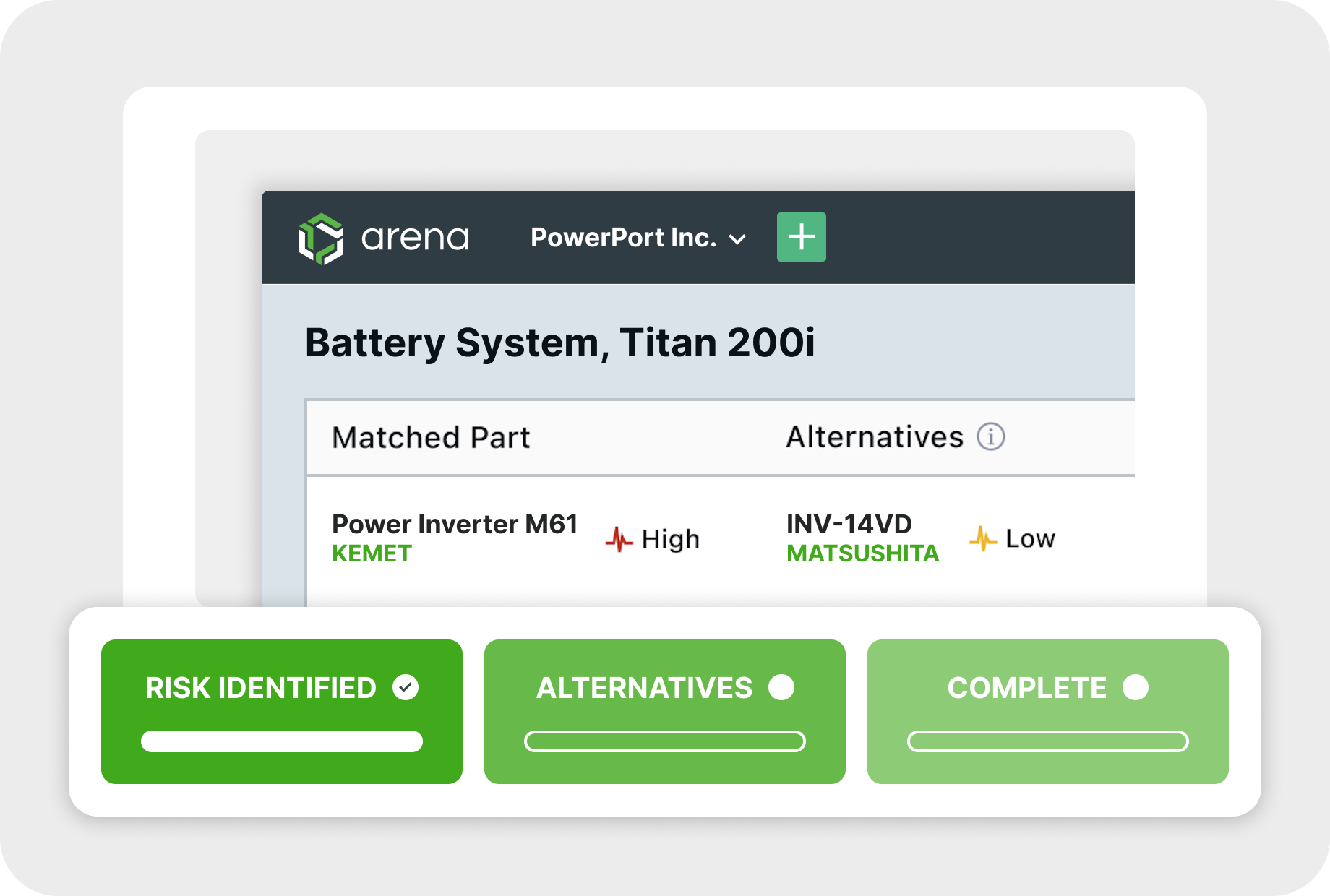

Marshall: It was a manual, time-consuming process. Component engineers had to research alternatives, verify compatibility, and ensure compliance—often across multiple sources. Typically, they relied on third-party databases to research alternative components. With supply chain intelligence now embedded in Arena, the process is fast and simple. You get real-time component risk insights from an industry-leading source directly within your existing PLM workflow.

HOW DOES SCI IMPACT THE COMPONENT ENGINEER’S ROLE?

Marshall: The role is evolving. SCI takes care of the tedious research, so engineers can spend more time focusing on strategic planning and risk mitigation. It’s a shift from reactive problem-solving to proactive design and sourcing.

CAN YOU SHARE A REAL-WORLD EXAMPLE OF A SOURCING CHALLENGE?

Marshall: Years ago, a customer was preparing a $5 million prototype run. They knew from early testing that certain memory devices and crystals didn’t work well together, even though they were technically compatible. By error, they selected a known bad combination and ended up with a warehouse full of unusable products. That costly mistake led them to adopt PLM and prompted us to develop custom features to prevent such issues in the future.

WHAT WAS THE ROOT CAUSE OF THAT COSTLY ERROR?

Marshall: The issue stemmed from a communication breakdown. Engineering knew about the incompatible parts, but procurement was not aware. If they had a centralized PLM system with supply chain intelligence like Arena, they could’ve flagged those parts and avoided the costly mistake.

HOW CAN COMPANIES MITIGATE RISK AND KEEP MANUFACTURING LINES RUNNING AMID GLOBAL DISRUPTIONS?

Marshall: Planning is key. Teams need tools to continually monitor their BOMs and flag high-risk items—whether due to end-of-life (EOL) status, pricing spikes, or compatibility issues. Arena SCI helps identify reliable, compliant alternatives quickly, reducing downtime and ensuring continuity.

WHAT FINAL ADVICE WOULD YOU OFFER TO COMPANIES NAVIGATING TODAY’S SUPPLY CHAIN CHALLENGES?

Marshall: Expect the best, but plan for the worst. Equip your teams with tools that provide real-time insights and trusted data. Arena SCI is a game changer. It allows users to instantly find and compare alternative parts, helping them stay ahead of disruptions and deliver products on time.

Thanks to Marshall for sharing these valuable insights!

As he reminds us, the key to thriving in today’s turbulent environment is preparation, communication, and the right technology. With solutions like Arena SCI, companies can move from reactive scrambling to proactive planning and monitoring—ensuring that alternative parts are not just available, but verified, compliant, and reliable. In a world where a single sourcing error can cost millions, investing in smarter systems and processes isn’t just strategic—it’s a necessity.

Learn more about managing supply chain risk in these turbulent times. Explore our resource page.