The Old Way: Siloed Teams, Disconnected Systems, and On-Premises Solutions

Traditionally, NPD has been centered around an in-house team of engineers that work independently to develop, test, and fine-tune the product design. In many instances, quality assurance, procurement, manufacturing, and other downstream players are not formally brought into the loop until the early production phase. This informal process works well if everyone is under the same roof and can readily review the design and exchange ideas. However, as more manufacturing steps are outsourced and teams become dispersed, the system breaks down. Eventually, companies encounter design for manufacturability (DFM) issues which prevent them from meeting their quality and cost targets, or even worse, getting products to market ahead of the competition.

Traditionally, NPD has been centered around an in-house team of engineers that work independently to develop, test, and fine-tune the product design. In many instances, quality assurance, procurement, manufacturing, and other downstream players are not formally brought into the loop until the early production phase. This informal process works well if everyone is under the same roof and can readily review the design and exchange ideas. However, as more manufacturing steps are outsourced and teams become dispersed, the system breaks down. Eventually, companies encounter design for manufacturability (DFM) issues which prevent them from meeting their quality and cost targets, or even worse, getting products to market ahead of the competition.

Throughout the NPD process, teams rely on a myriad of tools to manage product and quality information. Engineers typically start with mechanical CAD (mCAD), electrical design automation (EDA), and product data management (PDM) software to create and maintain their design files. Because these systems are intended for engineering workgroups, it is difficult for downstream product teams and external partners to provide input early in the design cycle.

Point software solutions, spreadsheets, and even paper are often used to develop and share critical records such as bills of materials (BOMs), design history files (DHFs), and standard operating procedures (SOPs). These records are ultimately saved to local hard drives, one or more shared drives, and/or physical storage sites.

Getting today’s distributed product team members to review, revise, approve, and implement changes can be challenging with these siloed, disconnected systems. It is difficult to identify the latest revision when information is stored and maintained in multiple locations. This gives way to engineering change orders with prolonged review cycles and mistakes which result in production errors and delays.

Tracking and maintaining quality documentation and processes is also labor-intensive and unreliable with this siloed approach. Team members must manually link quality information to the product record to keep everything in sync. Otherwise, there is no traceability or visibility into nonconformities that impact the final product. This could lead to the reuse of troublesome parts and subassemblies. In the case of highly regulated companies, it could also create compliance risks.

Lastly, these traditional NPD practices do not enable real-time collaboration across dispersed teams, slowing down the response to design errors, part shortages, and other issues that impact product launch schedules.

Challenges With On-Premises Enterprise Solutions

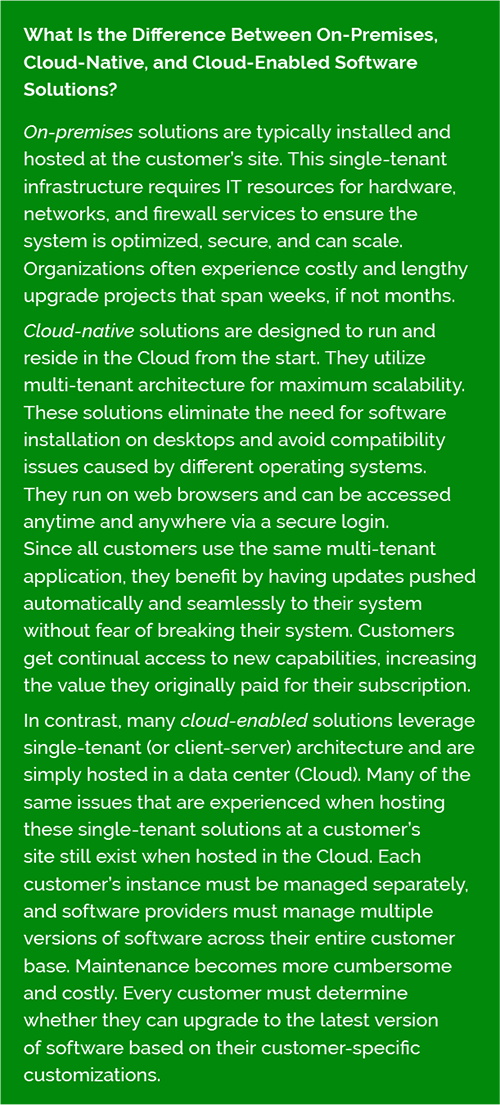

While many companies recognize the advantages of adopting a unified enterprise solution to manage NPD, some fall into the trap of investing in an on-premises platform. Oftentimes, businesses overlook hardware, software, firewalls, and other infrastructure required to use and access the system securely. Additionally, they lack the IT resources to implement robust security measures that safeguard sensitive intellectual property (IP).

Companies incur significant expenses from custom coding and upgrades in their effort to tailor the system to meet their unique requirements. As a result, they often get “rev-locked” on older versions of the software which prevents them from fully leveraging the system’s enhancements (part of their annual support expense which typically runs up to 25% of the software costs). Remote employees often experience difficulties accessing on-premises systems due to VPN connectivity or firewall issues. Ultimately, companies grapple with exorbitant maintenance costs, frequent downtime, limited functionality, and security vulnerabilities.

These issues decrease productivity, hindering organizations from reaching their product development milestones. Furthermore, IP and compliance risks loom, especially for those companies regulated by export controls and cybersecurity regulations (e.g., ITAR, EAR, CMMC).

To successfully coordinate the efforts of a globally dispersed team and accelerate NPD, manufacturers must drive more efficient, agile, and connected processes. By leveraging turnkey cloud-native

To successfully coordinate the efforts of a globally dispersed team and accelerate NPD, manufacturers must drive more efficient, agile, and connected processes. By leveraging turnkey cloud-native