From Reactive to Proactive: How Arena Supply Chain Intelligence Tackles Component Risk

Inside This Article

Although we’re years removed from the COVID-19 pandemic, sourcing electronic components remains a struggle. Shortages, long lead times, and volatile pricing haven’t gone away. And with new tariffs in the mix, product teams have even more to juggle—making it harder to deliver high-quality products on schedule.

We recently sat down with Arena Product Manager Nathan Ng and Senior Director, Head of GTM for Supply Chain, Guy Eron, to learn how the new supply chain intelligence (SCI) capabilities in Arena PLM and QMS can help companies proactively address these issues and mitigate component risks.

NATHAN AND GUY, PLEASE TELL US ABOUT YOUR ROLES AT ARENA BY PTC.

Nathan: I’ve been with Arena for over six years and currently lead the supply chain intelligence initiative as the principal product manager.

I connect with our customers to understand their pain points and how they’re leveraging Arena’s capabilities. This helps me identify opportunities to enhance their experience and drive more value from the platform. I then work closely with our engineering and customer success teams to translate those insights into clear product requirements and deliver impactful features that address users’ needs.

Guy: As the Head of GTM for Supply Chain, I sit at the intersection of product, sales, and marketing. I ensure alignment across these teams to build the right innovation roadmap, present Arena’s offerings effectively, and craft messaging that resonates with our audience.

WHAT INSPIRED THE CREATION OF SUPPLY CHAIN INTELLIGENCE?

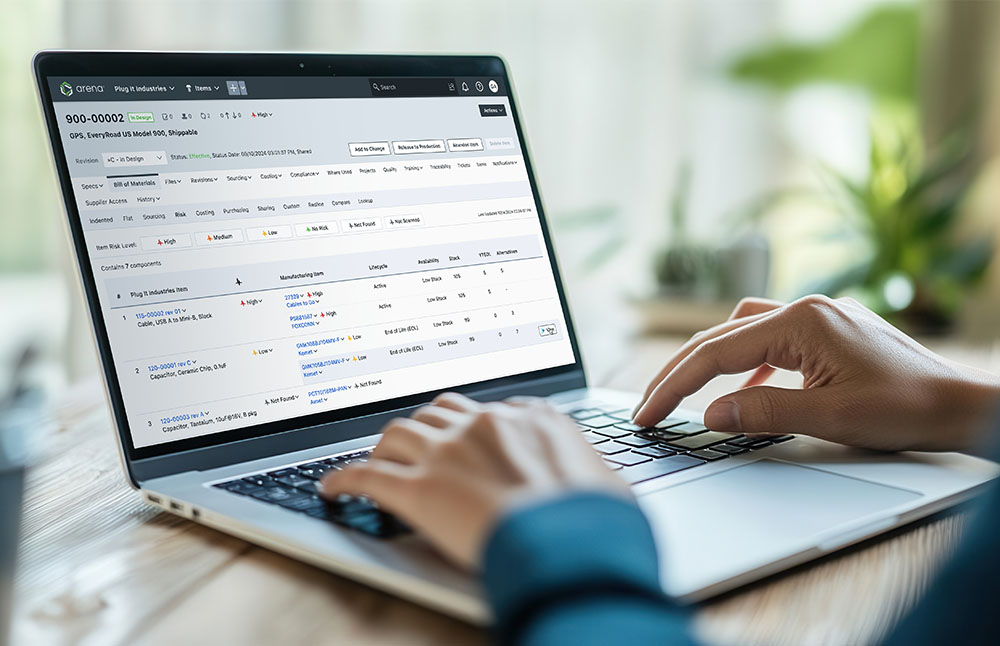

Nathan: Many of our customers depend on contract manufacturers to build their products. Through our conversations with them, we discovered a recurring challenge: they were constantly scrambling to source healthy electronic components from the right suppliers at competitive prices. Although information like availability, compliance, and stock was maintained in Arena, it was retrieved from multiple sources. Unfortunately, by the time procurement decisions were made, this information was often outdated. As a result, they were left with little room to proactively address supply chain issues.

Arena SCI gives us the opportunity to not only pull real-time component and risk information into the product design but also integrate it into some of our existing collaboration and engineering change capabilities—helping customers make faster, more informed decisions.

Guy: This is a big leap for us. Arena has always been about orchestrating internal product information and enabling different teams across the organization to collaborate on various aspects of product development. With SCI, we’re now bringing in external information from Accuris, an industry leading supply chain component data source, and turning it into actionable insights.

DESCRIBE THE KEY CAPABILITIES OF ARENA SCI IN THIS LATEST SOFTWARE RELEASE.

Nathan: The focus for this current release is component risk identification and mitigation. We want to help our customers easily identify any emerging risk in their supply chain and act fast. Users can now:

- View suggested component alternatives based on form, fit, and function

- Monitor item risk and supplier item risk across all levels of the bill of materials (BOM)

- Leverage a new “Lookup Details” action to access:

- Technical specifications

- Supply information

- Compliance details (i.e., RoHS, REACH, Prop 65, conflict minerals)

- Lifecycle status

- Alternative parts

- Country of origin

- Part change notices

Customers used to search through multiple manufacturer websites to obtain this information. Now they can access everything in Arena with a single click of a button.

Guy: And it’s not just about access. We translate this raw data into meaningful risk levels to help users address issues that need their immediate attention.

HOW DOES THIS NEW FUNCTIONALITY SET ARENA APART FROM OTHER PLM AND QMS SOLUTIONS?

Nathan: Other PLM or QMS platforms do not offer this level of integrated supply chain intelligence. Arena SCI is a fully productized solution. While other companies only offer custom PLM or QMS integrations for this capability, we provide Arena SCI as a built-in and scalable solution.

Another key differentiator is our ability to link component risk information directly to your BOMs, giving you full visibility into how supply chain issues affect your products throughout their lifecycle.

Guy: Arena is the first PLM solution to capture external supply chain information from a trusted source and not just rely on information from within the organization. By leveraging Arena SCI, customers gain access to the most accurate and up-to-date component library that’s available.

WHAT TYPES OF COMPANIES CAN BENEFIT MOST FROM ARENA SCI?

Guy: Companies that produce complex products, especially ones with significant electronic components, will benefit from this functionality. Their products are constantly evolving and require frequent changes. Arena SCI informs decisions throughout the change management and product development process by delivering teams real-time component data, continuous BOM health scans, and automatic risk alerts.

With Arena SCI at their disposal:

- R&D and engineering teams who are responsible for constructing the BOM can select optimal components from the start, ensuring products are designed right the first time.

- Operations or new product introduction (NPI) teams can streamline the transition to production—reducing delays, scrap and rework costs, and quality issues.

- Sustaining engineering teams can readily address supply chain issues throughout the product lifecycle and ensure on-time delivery.

In essence, Arena SCI embeds flexibility into BOMs, giving teams adequate time to respond to supply chain disruptions and purchase replacement parts from a reliable source at a reasonable price. They don’t have to worry about dealing with gray market suppliers or going back to the R&D team to revisit the design.

“Arena Supply Chain Intelligence empowers companies to move from reactive to proactive. Instead of discovering issues during procurement, teams get alerts early—giving them time to act before delays occur.”

-Nathan Ng, Arena Product Manager

CAN YOU SHARE SOME OF THE FEEDBACK FROM CUSTOMERS REGARDING ARENA SCI?

Nathan: The feedback from customers has been exceedingly positive! They appreciate Arena’s smart approach to mitigating component risk and the efficiencies they gain with the new functionality.

“Finding alternatives is really amazing.”

– Sourcing Manager, High-Tech Company“I preach being proactive to engineers. This helps us do that.”

– Engineering Lead, Manufacturing Prospect“This will be a huge time-saver.”

– Product Manager, Expanding Customer

HOW CAN CUSTOMERS TAKE ADVANTAGE OF ARENA’S COMPONENT RISK IDENTIFICATION AND MITIGATION CAPABILITIES?

Nathan: The new capability is included in all of Arena’s software packages and is readily accessible to customers. Arena users will see it enabled by default.

WHAT FUTURE UPDATES TO ARENA SCI ARE EXPECTED FOLLOWING THIS RELEASE?

Nathan: We’re just getting started. Upcoming enhancements include:

- Streamlined process for saving alternative parts directly with the product record

- Prominent field for country-of-origin information to help companies better address tariffs

- Component compliance information integrated into product lifecycle management processes

FINAL THOUGHTS: WHAT EXCITES YOU MOST ABOUT ARENA SCI?

Nathan: The built-in aspect of Arena SCI is what excites me most. Teams can manage component risk within Arena’s collaboration and change management processes. In turn, they improve product quality, accelerate time to market, and reduce costs.

Guy: I like the fact that we’re helping companies make more informed supply chain decisions earlier in the product development process to achieve design for excellence (DfX) goals.

Interested to learn more about Arena SCI? Visit our web page.