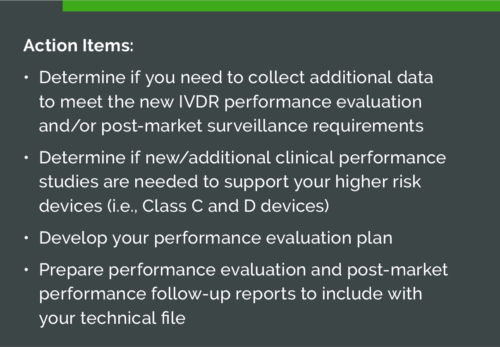

Under the new regulation, manufacturers will need to provide more in-depth clinical data to support safety and performance claims in both the pre- and post-market settings. Ultimately, more scrutiny will be placed on manufacturers to proactively collect and evaluate clinical data throughout the product lifecycle.

Performance Evaluations

The IVDR defines a performance evaluation as “a continuous process by which data is assessed and analyzed to demonstrate the scientific validity, analytical performance, and clinical performance of a device for its intended purpose as stated by the manufacturer.”

The IVDR defines a performance evaluation as “a continuous process by which data is assessed and analyzed to demonstrate the scientific validity, analytical performance, and clinical performance of a device for its intended purpose as stated by the manufacturer.”

Manufacturers should plan, conduct, and document performance evaluations in accordance with Article 56 and Annex XIII (Part A). Performance evaluations must be thorough and take into account both favorable and unfavorable data. The extent to which clinical data is collected should be in line with the nature, classification, intended purpose, and risk of the device, as well as the manufacturer’s safety and performance claims.

Performance Evaluation Plan (PEP)

The new regulation emphasizes the importance of early planning when it comes to performance evaluations. As such, manufacturers will need to develop a performance evaluation plan prior to gathering data. The performance evaluation plan should include:

Clinical Data Sources

Once a plan is established, manufacturers should identify all available clinical data that is relevant to the safety, performance, and intended purpose of the device. Sources of clinical data include:

Clinical Evaluation Assessment Report (CEAR)5

The clinical evaluation assessment report must be a part of the manufacturer’s quality management process. It should also be aligned with and reflected in other aspects of the technical documentation, such as:

Arena QMS Tip:

Quality TemplatesLeverage the Arena quality templates to help formulate your performance evaluation plan, performance evaluation report, post-market performance follow-up report, and other critical documents. Once created, they are linked to the product record and show the history of any changes that are made. Documents can be easily exported and included with your technical file.

Clinical Performance Studies

Clinical performance studies must be carried out by the sponsor/manufacturer if key aspects of the device’s performance cannot be verified by analytical performance studies, literature, or previous experience gained by routine diagnostic testing.

Summary of Safety and Clinical Performance (SSCP)6

Under the new IVDR, manufacturers will need to draw up a summary of safety and clinical performance (SSCP) for Class C and D diagnostics, other than laboratory-developed tests or investigational diagnostics. The SSCP should be validated by a notified body and made available to the public via the European database for medical devices (EUDAMED).

The SSCP serves as an important source of information for intended users—both healthcare professionals and patients. It is intended to help fulfill the objectives of the IVDR by enhancing transparency and providing adequate access to information about the safety and clinical performance of the diagnostic.

Performance Evaluation Report (PER)

The scientific validity data, analytical performance data, clinical performance data, their assessment, and the derived clinical evidence must be documented in a performance evaluation report and included with the technical documentation that is provided for the conformity assessment.

PERs should be updated once per year (at minimum) for high-risk diagnostics (i.e., Class C and D).

Post-Market Performance Follow-up (PMPF)

To confirm the safety and performance of a device throughout its lifecycle and ensure the continued acceptability of identified risks, manufacturers will need to conduct a post-market performance follow-up (PMPF) under the new IVDR requirements.

The PMPF should be conducted using a device that is already placed on the market and bears the CE Mark. It should also be conducted according to a formalized plan, which specifies the methods for proactively collecting and evaluating performance data. The manufacturer must decide the frequency of carrying out PMPF and document this rationale in the PMPF plan7.

The findings of the PMPF should be analyzed and documented in a PMPF evaluation report8 and included with the technical documentation. The conclusions of the PMPF evaluation report should be taken into account for the performance evaluation and in the risk management. If, through the PMPF, the need for preventive and/or corrective measures has been identified, the manufacturer should implement them.

If a manufacturer has determined that a PMPF process is not required for a specific device, then they must provide a justification and document it within the performance evaluation report (PER).

Notified bodies are expected to review the PMPF process, procedures, and reporting when they review the performance evaluation process and, also, how the data from the PMPF is used to update the performance evaluation report (PER) and risk management file.

The conclusions of the PMPF will be documented in the performance evaluation report (PER). For the higher risk class devices, such as Class C and D, the PER is expected to be updated at least annually, which means that the PMPF report should be updated annually as well. Important updates of the PMPF report should also be included in the periodic safety update report (PSUR) for Class C and D devices and in the summary of safety and clinical performance (SSCP), which should be updated as soon as possible, where necessary.

Section 2: Key Changes Under New IVDR

Economic Operator Roles and Responsibilities

Performance Evaluations, Performance Studies, and Post-Market Performance Follow-up

Post-Market Surveillance (PMS)

European Database for Medical Devices (EUDAMED)

Section 3: Quality Management System (QMS) Requirements

Section 4: Steps For A Successful EU IVDR Implementation