From Automation to Agency – Can the Future of Manufacturing Think for Itself?

Inside This Article

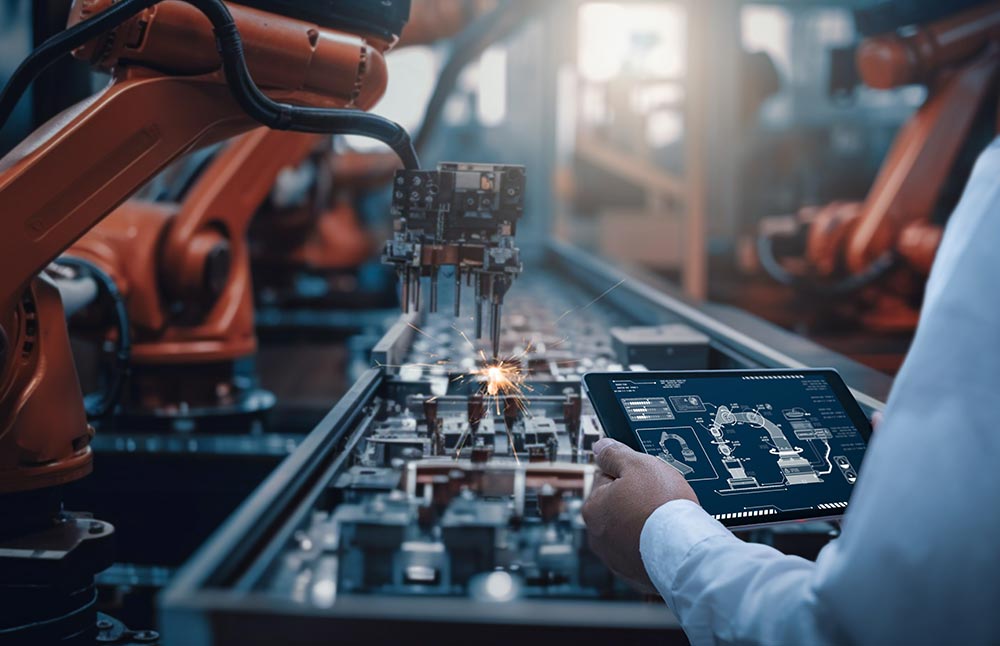

Manufacturing has always been shaped by innovation. Steam engines brought power. Assembly lines brought scale. Robotics brought speed.

Today’s factories are connected and increasingly intelligent, but they still operate within predefined limits. The next leap forward isn’t about machines doing more tasks, rather, it’s about enabling them to respond, adapt, and optimize in real time.

This shift marks the transition from automation to agency.

Why Automation Alone Is No Longer Enough

For decades, automation has delivered efficiency through fixed instructions. It has helped manufacturers scale predictable workflows and reduce human error. But when those workflows encounter unpredictability, automation falls short.

If a process deviates, automation stops. If a sensor fails, automation misfires. If demand changes mid-shift, automation does not adapt. In today’s manufacturing world, where supply chains are volatile and precision is non-negotiable, rigidity has become a liability.

Many engineering and operations leaders are now asking: “Isn’t this just another version of smart automation?” That question is valid. But agentic systems are not just an upgrade. They are a leap forward in how factories sense, reason, and respond.

What Makes Agentic Systems Different

Agentic systems are not programmed to follow instructions. They are built to make decisions. Using semi-autonomous agents, machine learning, and live data, these systems interpret changing conditions, weigh alternatives, and take action. They do not wait for human approval. They pursue goals.

Agentic Systems Vs. Traditional Automation and AI

Aspect |

Traditional Automation |

Basic AI |

Agentic Systems |

| Adaptability | Low | Medium | High |

| Human Role | Manual intervention | Supervision | Strategic guidance |

| Decision-Making | Pre-set rules | Suggested actions | Autonomous decisions |

| Goal Setting | Fixed | Conditional | Continuously optimized |

Agentic systems reason through multiple scenarios and optimize on the fly. They operate closer to how a seasoned engineer would, not how a rule-based machine does.

For example, if a tool wears down mid-run, an agent can instantly reroute the job to a backup cell, adjust the timeline, and flag the quality team without human intervention. It does not wait. It acts to preserve throughput and quality.

Or take a scenario where material properties change due to a new supplier. Traditional automation would continue the same program, risking defects. An agentic system, however, would notice the shift in inputs, reconfigure the machine parameters in real time, and adjust quality checks on the fly.

For operations teams worried about adding complexity, agentic systems are designed to complement, not replace, existing automation and MES or ERP systems. They sit atop your current infrastructure and act as a real-time decision layer without requiring a disruptive overhaul.

Already in the World: How Companies Are Using Agentic AI to Redefine Manufacturing

This is not theoretical. In 2025, early adopters in the manufacturing sector began deploying agentic AI across global production lines. These autonomous systems analyzed real-time sensor data and responded proactively to early warning signs (cutting unplanned downtime significantly in some cases).

In these rollouts, edge devices coordinated across facilities. When an issue was detected in one location, intelligent recommendations were shared across the network, allowing similar machines in other plants to adjust—preventing disruptions before they occurred.

These outcomes aren’t just operational wins. They mark a fundamental shift in what’s possible when machines can reason through complex scenarios with speed and precision that humans alone cannot match. Agentic manufacturing is no longer aspirational. It’s already here.

Cloud technology and AI are reshaping product development by improving collaboration, increasing visibility, and connecting global teams in real time. These tools support faster decisions, reduce risk, and streamline workflows without replacing human expertise. Together, they help manufacturers adapt quickly, strengthen resilience, and deliver higher-quality products to market.

Why It Matters Right Now

Factories are facing a future that will reward flexibility, not just scale. Customer demands change daily. Global constraints hit supply with little warning. Skilled labor is in short supply.

Agentic intelligence is not a replacement for people but a co-pilot that never sleeps, never hesitates, and never misses a deviation. When machines go down, agentic systems reroute workflows in real time. When inputs shift, they adapt schedules instantly. When quality metrics drift, they intervene before scrap accumulates.

Agentic systems also reduce operator fatigue and decision burden. By handling thousands of micro-decisions per shift, they prevent overwhelm and free up teams to focus on high-impact problem-solving. This shift builds not only resilience but long-term workforce sustainability.

A Human Future, Not a Machine Takeover

Agentic systems are aligned with the principles of Industry 5.0. This is not about removing human roles but elevating them.

Operators become problem-solvers, engineers guide strategy, and teams overall get time back to improve systems instead of fighting fires. With agentic systems, the factory becomes an ecosystem where human creativity and machine intelligence drive results together.

Teams that once operated in silos—maintenance, scheduling, quality—now align around shared goals. Agents act as real-time translators between systems and people, turning factory data into action in ways that are meaningful to every role on the floor.

Where to Begin

If your factory still relies on rule-based automation alone, you are operating with tools designed for yesterday’s world. The volatility, complexity, and opportunity of modern manufacturing call for a more intelligent foundation.

Start by asking:

- Which decisions still require human intervention under pressure?

- Where does rigidity cause friction or delay?

- What would it mean to empower machines to pursue outcomes on their own?

Answering those questions is the first step toward building a factory that thinks for itself and a workforce that is freed to do its best work.

To explore the full framework behind agentic intelligence, download First Resonance’s ebook: The Agentic Shift: Building Intelligence Into the Fabric of Industry