EOL Components and Last Time Buys: Navigating Supply Chain Challenges in Medical Devices

Inside This Article

As supply chains become more precarious, manufacturers—especially in the medical device space—face mounting risks. A single component shortage could critically delay or even halt a product launch.

I recently caught up with Arena Account Executive Aubray Helm to learn about her previous role managing complex supply chains in the medical device industry. With a wealth of experience navigating regulatory hurdles, component lifecycles, and the challenges of outdated systems, Aubray offers a compelling look at how modern supply chain intelligence (SCI) solutions could have transformed her past work—and how they’re poised to transform the industry today.

Aubray, Please Tell Us About Your Professional Experience Before Joining PTC.

Aubray: For several years, I worked in supply chain for a medical device company in the San Francisco Bay Area. We designed and manufactured our own devices and did contract manufacturing for companies like Johnson & Johnson, Boston Scientific, and Medtronic.

What Were Your Primary Responsibilities in That Supply Chain Role?

Aubray: I collaborated across the product lifecycle, from new product introduction (NPI) through to service. That meant working closely with engineering on new designs, managing component selection, and ensuring availability.

The company was small—about 250 employees—so we managed multiple product lines. I handled everything from chassis and overlays to printed circuit boards (PCBs) and harnesses. My role was broad and hands-on.

How Does Supply Chain in Life Sciences Compare to Other Industries?

Aubray: It’s more regulated. In high-tech, you can get a product to market in a couple of years. In life sciences, the FDA approval process can take much longer. This extended timeline increases the risk that electronic components specified during new product development (NPD) will go end of life (EOL) before production.

What Were Some of the Biggest Obstacles You Faced?

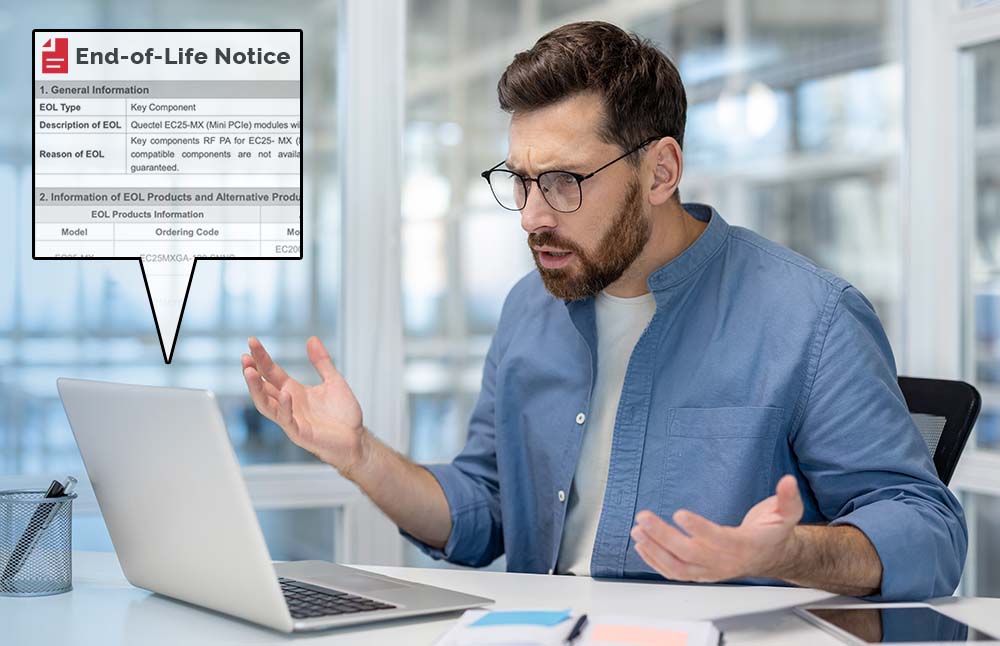

Aubray: Component lifecycle management was a huge issue. A lot of it was manual, involving part-by-part checks. We did not have electronic component databases or cloud product lifecycle management (PLM) solutions to gain a clear view of component risk. Instead, we relied heavily on outdated manufacturing resource planning (MRP) systems and document control.

By the time we went into production, many parts had already reached EOL. Changes to essential components like field programmable gate arrays (FPGAs) or power supplies triggered a 510(k) re-submission to the FDA, introducing additional expenses and delays. This is why design for supply chain (DfSC) is so crucial for life sciences companies today.

In many instances, we would buy enough inventory to last several years and keep it as safety stock to mitigate the impact of EOL components. Consequently, we incurred high holding costs.

How Did You Handle Eol Notifications and Last Time Buys?

Aubray: We often missed EOL notifications and last time buy opportunities due to our reliance on manual processes and siloed systems. If we missed a last time buy and there was no drop-in replacement, we had to go to the gray market—buy from brokers, test the parts, and hope for the best. It was expensive and risky.

How Did You Receive Product Change Notifications (PCNs)?

Aubray: We usually received PCNs via email from our distributors. We tried using external component databases, but we couldn’t load the full BOM most likely due to licensing or cost constraints.

How Do You Think Modern Solutions Like Arena SCI Could Have Transformed Your Supply Chain Management Experience?

Aubray: An integrated solution like Arena Supply Chain Intelligence (SCI) would have been invaluable. The system’s continuous BOM scans and automatic EOL risk alerts would have enabled us to be more proactive at selecting healthy components for design, planning, service, and spare parts.

Even today, with issues like shifting tariffs, having that level of electronic component insight from the start is critical. I’m now genuinely excited to talk to organizations about SCI because I know how much it can help.

Any Final Thoughts on the Future of Supply Chain Management?

Aubray: Supply chain intelligence is no longer optional. Whether you’re dealing with tariffs, natural disasters, or component shortages, having real-time component insights and proactive alerts is essential. I’m thrilled to be part of a team that’s bringing these advancements to life.

Thanks to Aubray for sharing these insights!

Her story is a powerful reminder of how far Cloud PLM and supply chain technologies have come—and with continued advancements in artificial intelligence (AI), how much potential still exists for industries like life sciences.

Learn more about transforming your supply chain in these turbulent times. Visit our resource page.