-

- North America

- EMEA

The following industries have been identified as high priority for sustainability, circularity, and economic impact.

They include:

The Battery Regulation mandates the implementation of battery passports by February 18th, 2027. Passports transform the battery industry by enhancing sustainability, circularity, and safety.

Digital passports can help the chemical industry increase circularity for chemical products by enabling supply chain traceability, quick verification of safety credentials, and improving upstream visibility. Passports have EOL instructions, improving their recyclability and capacity for safe disposal. Passport requirements for chemical products will be delivered via a delegated act under the ESPR between 2026 – 2030.

Regulations such as the ESPR and construction products regulation (CPR) mandate passports for the construction industry to help reduce the industry’s environmental impact. Passports can provide a platform for sharing product sustainability information with construction stakeholders to enable environmentally conscious supply decisions. This can lead to more sustainable construction projects and mitigate negative reputational impact. DPPs under the CPR are expected to come into effect in 2027.

Currently, only 20% of all e-waste is recycled. Passports can reduce waste and improve circularity in consumer electronics by incorporating recyclability information and detailed disposal instructions specific to each item. This can help to reduce the amount of e-waste sent to landfills. Each product’s verifiable raw material composition is displayed for stakeholders to examine, assisting with retrieving rare earth materials from e-waste. Passport requirements for electronics products will be delivered via a delegated act under the ESPR between 2026 – 2030.

On a yearly basis, 12.2 million tons of furniture waste is generated globally, with over 80% of that ending up in landfills. Passports can help the furniture industry increase its overall recycling rate (currently 0.3%) by providing accessible recycling and remanufacturing instructions. The verifiable sustainability data included within passports can also help furniture companies prove that their green claims are genuine, tackling greenwashing and empowering customers to make environmentally conscious purchases. Passport requirements for furniture products will be delivered via a delegated act under the ESPR between 2026 – 2030.

In addition to providing sustainability information and raw material sources for luxury goods, passports enable enhanced supply chain traceability to help customers identify counterfeit goods and allow brands to remove unscrupulous suppliers from their network. When combined with blockchain, passports can contain tamper-proof ownership records, allowing more secure trading on second-hand marketplaces. DPP requirements for luxury goods will be delivered via a delegated act under the ESPR between 2026 – 2030.

Roughly 400.3 million metric tons of plastic was produced across the globe in 2022, with plastic production generating some of the highest CO2 emissions of any industry. Passports can provide a detailed amount on the carbon emissions produced during plastic manufacture for each of a company’s products. The digital passport provides a holistic view of a company’s emissions profile and identifies and monitors high-emission processes taking action to make them greener. Passport requirements for plastics products will be delivered via a delegated act under the ESPR between 2026 – 2030.

Approximately 92 million tons of textile waste is produced each year and is expected to grow to 134 million tons by 2030. The ESPR has given textiles a specific mandate to help curb this waste by introducing digital passports by the year 2030. DPP information will help boost the circularity of textile products by providing recyclability and EOL instructions and tackle greenwashing in the industry by giving stakeholders easy access to sustainability, manufacturing, and raw material data for individual products.

Discarded toys contribute to environmental hazards such as microplastics and greenhouse gas emissions as 90% of toys are made of plastic, with 80% of those toys ending up in landfills, incinerators, or the ocean. Passports are mandated by the Toy Safety Regulation to help improve circularity in the industry by providing access to recyclability information. They also provide verifiable safety information that can be accessed by customers, customs officers, and regulators, helping to reduce the number of unsafe toys on the market.11

The new regulation establishes EU-wide sustainability requirements for all types of batteries entering the European market, including electric vehicle batteries (EVBs), waste portable batteries, battery energy storage systems (BESS), industrial batteries, batteries for light means of transport (LMT), such as electric bikes, and starting, lighting, and ignition (SLI) batteries.

As a requirement from EU Battery Regulation starting in February 2025, battery manufacturers will be required to have a carbon footprint report. By 2027 batteries must comply with maximum carbon footprint thresholds, which will tighten over time to push manufacturers toward more sustainable production processes and to encourage a circular economy. The Battery Regulation also mandates specific minimum percentages of recycled materials in batteries such as nickel, lithium, lead, and cobalt.

According to the latest forecast, the battery industry is expected to be DPP-ready by February 2027. Passports will include general information about the battery model, manufacturer, battery category, its capacity, batch traceability, component sourcing information, and general information on material composition (such as hazardous substances and critical raw materials).

Additionally, consumers will be able to access the carbon footprint declaration, information regarding the responsible sourcing of materials (in line with due diligence policies), recycled content, and share of renewables.

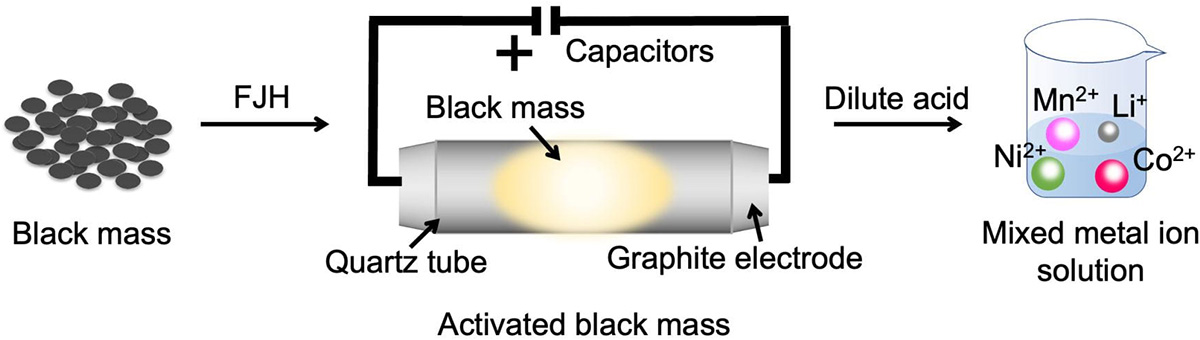

Black mass recycling is a process that extracts valuable materials like lithium, manganese, cobalt, nickel, and other materials from used lithium-ion batteries. These materials are essential for manufacturing new batteries and can be carefully extracted, processed, and reincorporated into new batteries. However, since their natural supply is limited, extracting them from untouched sources is environmentally damaging.

As the adoption of electric vehicles surges, there’s an escalating demand for metals such as cobalt and lithium. These minerals are predominantly found in select regions of the world such as the Democratic Republic of Congo, one of the largest global cobalt producers, while countries like Argentina, Chile, and Australia lead in lithium production. These specific geographies make minerals scarce and prone to supply chain disruptions due to political, environmental, or economic factors.

Before restrictions, many companies in Europe and North America were exporting large quantities of black mass to China for processing because it was cheaper to process there. China had a large market for importing this material for recycling. With environmental concerns, they have significantly restricted black mass imports over time, classifying it as hazardous waste.

On December 31, 2024, China issued its first national standard for black mass material used in lithium-ion battery recycling formally named GB/T 45203-2024 Black mass for lithium-ion battery. It will take effect July 1, 2025, according to China’s national public service platform for standards information. The new standard will categorize black mass into two types: type 1 being black mass produced from lithium-ion batteries containing nickel and cobalt, and type 2 being made from lithium iron phosphate (LFP) batteries.12

Currently, the largest importers of black mass are in South Korea, Southeast Asia, and India, but demand in all three locations has decreased over the last few months. Black mass is expected to gradually find its way into battery production, pending quality checks and qualifications; consequently, black mass will be part of digital passport requirements.

Source: Rice University

A Practical Guide to the Digital Product Passport - Introduction

The Concept Behind the Digital Product Passport (DPP)

Understanding DPP Laws, Regulations, and Business Requirements

Industries Affected by the DPP Mandate

What Type of Information Is Stored Inside a DPP?

Blockchain Technology: The Foundation for Building a DPP

Companies Are Using PLM to Manage DPP Information