What is a Bill of Materials (BOM) and How Do You Create One?

What is a Bill of Materials (BOM)?

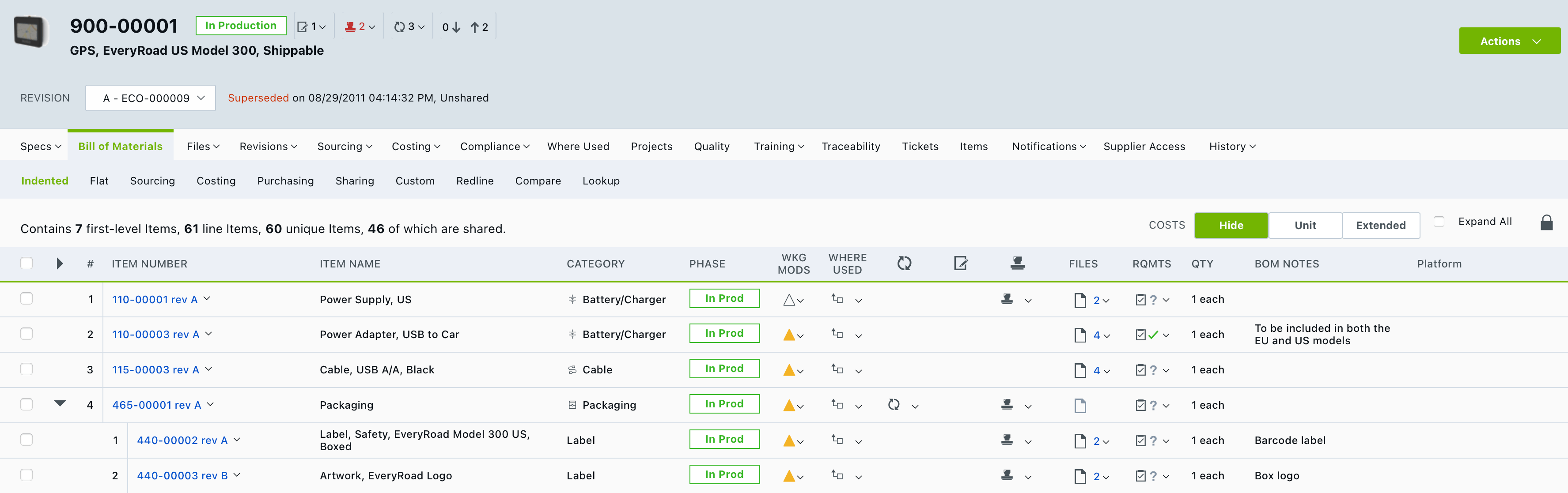

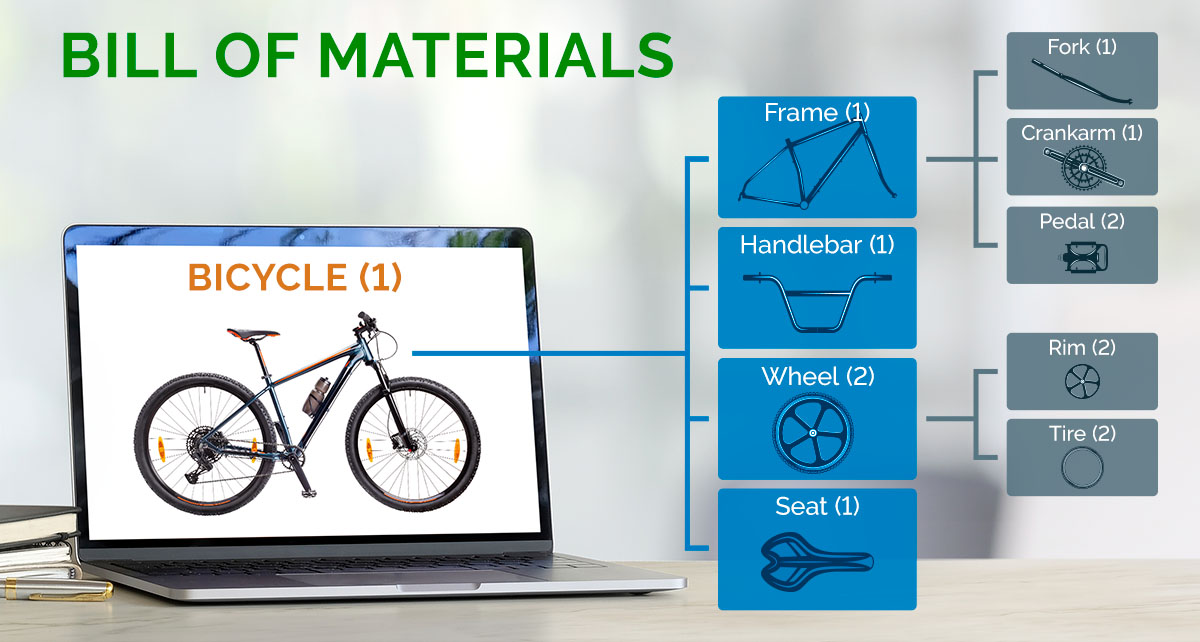

A bill of materials (BOM) is a comprehensive list of parts, items, assemblies, subassemblies, intermediate assemblies, documents, drawings, and other materials required to create a product. The BOM can be thought of as the recipe used to create a finished product, presented in a hierarchical format. Depending on the product, it may include mechanical (hardware), electrical (e.g., ICs, PCBAs), software, and related documents and drawings.

The bill of materials and associated records describe the materials required to source and build an assembly. All manufacturers building products, regardless of their industry, get started by creating a bill of materials (BOM).

Because the bill of materials pulls together all sorts of product information, it is common that several disciplines (design and engineering, document management, operations, manufacturing, purchasing, contract manufacturers, and more) will collaborate on the product information contained within the BOM to enable accurate production. Furthermore, engineering teams will create engineering bill of materials (EBOMS) and the manufacturing teams will rely on manufacturing bill of materials (MBOMS).

The BOM helps guide positive results as products evolved from design, through development, and ultimately volume production—so it is critical to create and share an accurate and up-to-date version of the BOM with all teams. And for companies that rely on supply chain partners, it’s important to provide effective revision control throughout the new product development and introduction (NPDI) process. Any time the BOM is shared with a contract manufacturer (CM) or supplier, it should be the latest released revision to prevent unnecessary production mistakes and product launch delays.

Intelligent BOM Management for Today’s Innovators

For product companies working with distributed teams and supply chain partners, collaborating on the latest bill of materials (BOM) is critical to reduce production errors and shipping delays. In this ebook, we identify the problems with traditional, manual approaches and explain why Arena provides a more intelligent and comprehensive way to control, share, and release accurate BOMs and related product information.

Bill of Materials (BOM) Management topics covered:

- BOM management challenges such as change, revision and compliance management

- Communication issues with project teams, suppliers and contract manufacturers

- Comparison of manual vs. automated BOM management tools

What to include in an effective bill of materials

Because one of the main functions of the BOM is to ensure that the product is built right, it is best to include specific pieces of product data in the BOM record. Whether you are creating your first bill of materials or are looking for ways to improve how you create a bill of materials, here is a high-level list of information to include in your BOM record:

- BOM Level—Assign each part or assembly a number to detail where it fits in the hierarchy of the BOM. This allows anyone with an understanding of the BOM structure to quickly decipher the BOM.

- Part Number—Assign a part number to each part or assembly in order to reference and identify parts quickly. It is common for manufacturers to choose either an intelligent or non-intelligent part numbering scheme. Whichever scheme you use, make sure you avoid creating multiple part numbers for the same part.

- Part Name—Record the unique name of each part or assembly. This will help you identify parts more easily.

- Phase—Record what stage each part is at in its lifecycle. For parts in production, it is common to use a term like ‘In Production’ to indicate the stage of the part. New parts that have not yet been approved can be classified as ‘Unreleased’ or ‘In Design’. This is helpful during new product introduction (NPI) because it allows you to easily track progress and create realistic project timelines.

- Description—Provide a detailed description of each part that will help you and others distinguish between similar parts and identify specific parts more easily.

- Quantity—Record the number of parts to be used in each assembly or subassembly to help guide purchasing and manufacturing decisions and activities.

- Unit of Measure—Classify the measurement in which a part will be used or purchased. It is common to use ‘each’, but standard measures like inches, feet, ounces, and drops are also suitable classifications. Be consistent across all similar part types because the information will help make sure the right quantities are procured and delivered to the production line.

- Procurement Type—Document how each part is purchased or made (i.e. off-the-shelf or made-to-specification) to create efficiencies in manufacturing, planning, and procurement activities.

- Reference Designators—If your product contains printed circuit board assemblies (PCBAs), you should include reference designators that detail where the part fits on the board in your BOM. Capturing this information in the BOM can save time and help you avoid confusion down the road.

- BOM Notes—Capture other relevant notes to keep everyone who interacts with your BOM on the same page.

Have a single software system to document and control the entire product record, including the BOM, helps ensure all engineering, quality, procurement, and manufacturing teams stay on the same page at all times. The best way to prevent siloed communication is using cloud-based BOM management capabilities found in product lifecycle management (PLM) software systems.

In addition to capturing and managing an accurate revision-controlled product record, you should also consider the following questions when creating a bill of materials.

4 key questions you must answer before creating a bill of materials

- Will you document consumables in your BOM record? Many manufacturers second-guess the decision to include glue, wires, fasteners, and other non-modeled parts like labels and boxes in their BOM record. But if the part does not make it into your BOM, it might not make it into your product. So take the time to document these parts.

- How will you attach files to your BOM record? As you create your BOM, keep records of supporting documentation like CAD drawings and work instructions. It is critical to link these files with their specific component found at the appropriate level of the BOM to avoid confusion, quality issues, and manufacturing scrap and rework.

- Who is going to use the BOM record? It is important to include as many details as possible in your BOM. You may never interact face-to-face with some of the people utilizing your BOM, so it should convey all the information they might need throughout the product’s lifecycle.

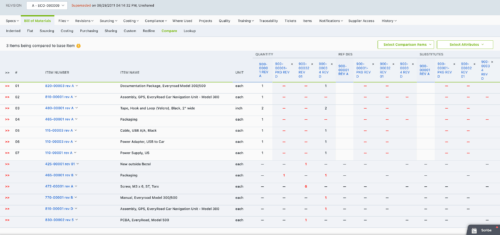

- How will you reconcile your BOM record? Your BOM record may go through several iterations during the design phase. Make sure you can easily compare past and present revisions of the BOM to highlight what has changed. You should also be able to easily traverse up or down the indented bill of materials to see all components and subassemblies and how they fit together. And, you should be able to see what BOM changes were created by specific, linked engineering change orders (ECOs). This allows you to review when and by who changes were approved.

Optimizing Production Efficiency With Effective BOM Management Processes

A reliable bill of materials (BOM) management systems streamline the development, maintenance, and tracking of component lists necessary for product assembly. By integrating BOM management and enterprise resource planning (ERP) systems, businesses can increase departmental collaboration across design and manufacturing, decrease errors, and improve accuracy. These streamlined processes lead to improved cost control, enhanced manufacturing efficiency, reduced scrap and rework, and a faster time to market.

Implementing appropriate BOM management practices ensures traceability and the accurate recording of all product variations, thereby supporting version control and industry standard compliance.

Investing in cloud BOM management software helps organizations maintain consistency, meet customer demands, and stay competitive in a rapidly evolving market. A BOM management implementation case study underscores the critical role of effective bill of materials management in optimizing manufacturing processes and ensuring product quality.

Read how Nutanix reduced their BOM errors to absolute zero.

An accurate BOM supports efficient manufacturing processes

Creating a bill of materials is not only a necessary step in the product development process, but it is also what makes successful commercialization a reality. Before you create a BOM record, consider who will use the information and how you will manage all associated parts and documentation. To learn more, click here and check out our free BOM template.