Turning Turbulence Into Opportunity: A Playbook for Agile, Resilient Supply Chains

Inside This Article

Supply chain disruptions have been hitting companies from all sides. Unprecedented tariff policy shifts, geopolitical instability, and natural disasters have all increased in recent years, causing unforeseen supply chain disruptions. Production shutdowns, labor and material shortages, shipment delays, longer lead times, higher costs, and lower quality have made it imperative that these risks be considered in creating an agile supply chain strategy. To take effective action and prepare for what’s next, product companies need a game plan for supply chain risk management (SCRM) that keeps all internal stakeholders and supply chain partners aligned.

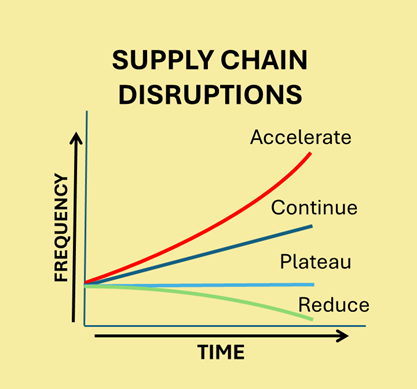

Most leaders and industry players agree that supply chain disruptions are unlikely to reduce or plateau, but rather, accelerate. Among global supply chain leaders, 70% expect disruption to be the new normal, yet only one in five believe their networks can handle it, highlighting the urgency to build supply chain agility and resilience.1

Defining Supply Chain Agility and Resiliency

Supply chain agility emphasizes speed and adaptability, prioritizing flexibility, responsiveness, visibility, and technology enablement. A resilient supply chain is built to withstand, adapt to, and recover from disruptions while continuing to deliver value and includes characteristics of redundancy, risk management, sustainability, and continuity. In short: Agility is about dodging the punch. Resilience is about taking the hit and staying on your feet.

Increase Supply Chain Agility: Take These Steps First

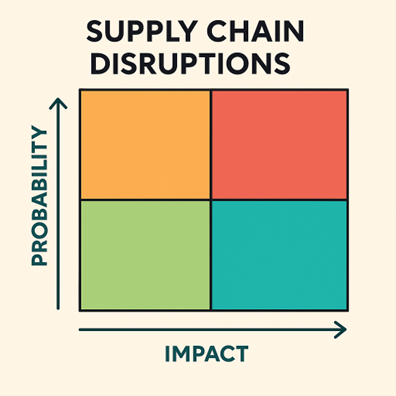

1. Map and rank your supply chain to quantify probability and potential impact of risks

- Rank based on probability of disruptions from tariff/trade policies, geopolitical instability, and natural/environmental/pandemic calamities. Then rank the potential level of operational impact including duration, cost, quality, capacity, and lead times.

- Include critical component source locations and production, distribution, and service locations

- Include customer demand risk based on market locations

2. Develop scenarios to mitigate highest ranked risks

- Create scenarios based around highest probability disruptions with the most impact

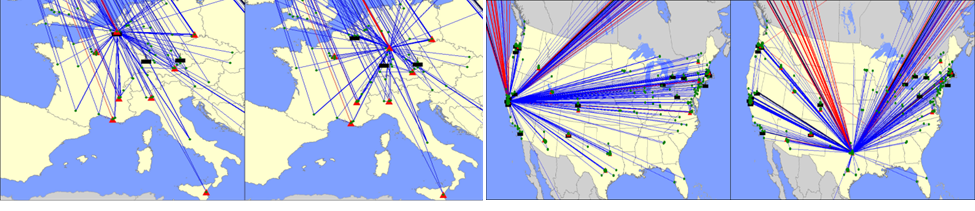

- Evaluate scenarios to define optimized responses—focus on opportunities to avoid/mitigate risks and increase agility, such as by reducing distances

- Prioritize and develop action plans for implementing changes with clear responsibilities, timing, and objectives

Supply Chain Network Modeling Scenario Comparison

3. Invest in smart solutions for better supply chain insights

New technologies are enabling rapid data acquisition, evaluation, and decision-making. Examples include:

- Supply chain network modeling solutions enable quick updates as conditions change and rapid evaluation of new scenarios as needed

- Supply chain intelligence (SCI) solutions, such as Arena SCI, monitor and highlight component-related issues and supply chain risks proactively to identify alternatives early

- AI-enabled supply chain data orchestration, forecasting, and optimization, integrated with real-time external data sources, provide increased accuracy and faster response times

4. Develop an integrated process to respond to changes on an ongoing basis

- Integration speeds everything up—Gartner ranks integrated business planning (IBP) as the highest-impact capability for supply chain performance in 2025

- Change the focus from optimizing functions independently to optimizing the whole system

- Utilize this process to review, adjust, execute, and repeat

Build Greater Supply Chain Resilience: Take These Steps Next

Building a resilient supply chain does not happen overnight. Proactive steps must be identified, planned, and implemented over time to enhance supply chain resiliency. Key first actions include:

1. Diversify sourcing—vary your supplier base across regions

- Diversifying suppliers across regions strengthens resilience, minimizes risk, and ensures agility in responding to disruptions

- Diversifying while simultaneously deepening relationships with strategic partners creates pragmatic resilience

- Strategic planning and strong partnerships drive long-term flexibility and allow quick pivots for operational continuity

2. Realign production and distribution locations

- Focus on resiliency—Consider the probability of disruptions from tariff/trade policies, geo-political instability, and natural/environmental/pandemic calamities and the potential level of operational impact on costs, quality, capacity, inventory, and lead times

- Nearshoring and reshoring—Evaluate options for shifting production closer to key markets to reduce dependency on global shipping, minimize exposure to tariff/trade disruptions, and improve responsiveness

- Sustainability considerations—Prioritize eco-friendly distribution hubs and optimizing routes to minimize carbon footprints

- Create dynamic supply chain ecosystems—Avoid rigid models; adopt adaptive networks that can quickly adjust to disruptions and market shifts (e.g., partners with a single location vs. partners with a network of locations)

- Leverage supply chain network modeling, scenario planning, and AI tools to assess scenario options, demand patterns, transportation costs, sustainability impacts, and geopolitical risks to determine optimal locations

3. Optimize inventory management to increase resilience

- Expand beyond just-in-time models to more flexible inventory strategies to mitigate shortage risks

- Develop targeted strategies for increasing safety stock for critical components while maintaining lean practices elsewhere

Finding Balance Between Supply Chain Agility and Resiliency

The goal supply chains must achieve is to find the right balance, being agile enough to adapt and resilient enough to endure. Companies that prepare and can successfully navigate ongoing and increasing supply chain disruptions will thrive in coming years. Achieving a balance between priorities for cost/efficiency and agility/resilience ensures your company transforms from reactive crisis management to planned scenario execution with a process for maintaining this balance as challenges evolve and market dynamics change.

Arena by PTC and The Results Group work together to build your supply chain resilience with actionable, data-backed insights and processes. The Results Group supply chain tariff analysis allows companies to map modeling scenarios based on inputted data. Learn how their services help companies build agile, resilient chains here.

References: