Revolutionizing Manufacturing: Integrating Arena PLM With ION Factory OS

As the pressure mounts for manufacturers to deliver in shorter timelines because of increased competition and the urgency to solve a myriad of climate-related challenges, legacy ways of doing things have become an insurmountable hindrance to progress.

Overcoming Challenges in Product Lifecycle Management With Advanced Solutions

The problem? Spreadsheets, generic workflow management systems, and traditional manufacturing execution systems (MES) have resulted in blind spots, gaps, and inaccuracies that make managing all aspects of a product’s lifecycle—from inception through operation, delivery, and maintenance—virtually impossible.

In complex, discrete manufacturing, especially where traceability and compliance are critical, part serialization, loT-tracking, supplier quality, and other functions require sophisticated systems to manage and track products as they come in the front door, go through multiple value-add processes, and get delivered to the customer.

Bridging Gaps With Arena PLM and ION Factory OS Integration

Getting a full depiction of the process and an accurate living digital thread is no easy feat—it requires platforms with modern architectures and connectivity between people, systems, and teams. Enter a pre-built integration between Arena PLM and First Resonance’s ION Factory OS, two key ingredients that make up the emerging concept of a factory tech stack.

Seamless Integration: From Design to Execution With Arena PLM and ION Factory OS

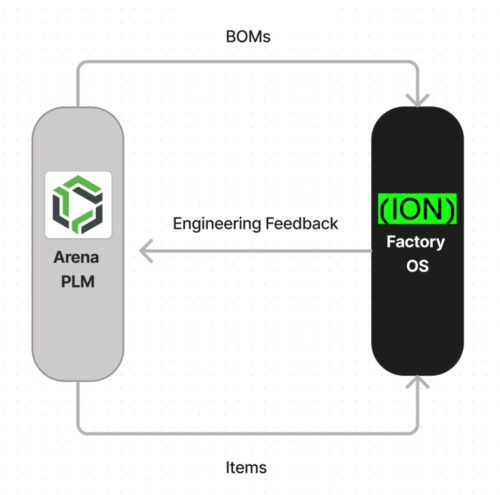

Arena PLM primarily covers the design phase and associated processes of a product’s development and ION Factory OS picks up to support the execution phase and beyond. The tight integration of the two systems enables the ability to trace the true as-built record of the hardware that is produced.

From Design to Production: Integrating Arena PLM With ION Factory OS

Most heavily used in the engineering phase of the product development process, where things are still in the design phase, Arena PLM is the starting point for identifying and organizing the parts needed for production, how they go together, and integrating design revisions. From there, ION Factory OS ingests the information (including complex multilevel BOMs) to support the next phase—production.

Arena PLM <> ION Factory OS Integration

Ensuring Synchronization and Efficiency in Product Development and Manufacturing

The seamless transfer of data doesn’t stop there though. The bilateral connection between the two systems ensures buyers and manufacturing engineers are never out of sync even as products move through the assembly line, adjustments are made, and final products are delivered to customers. Conversely, changes made in the design phase are automatically reflected in the manufacturing process. This helps in efficient change management, reducing the risk of errors and ensuring that the latest design specifications are followed during production—making further iteration possible even after production has started.

Revolutionizing Manufacturing With First Resonance’s ION Factory OS

A cloud-based manufacturing software system that brings together your supply chain, work instructions, and issue tracking, First Resonance developed ION Factory OS in response to the rigid and disconnected systems that continue to plague manufacturers trying to adapt to industry 4.0 principles.

Enhancing Innovation and Compliance With ION’s Proactive Quality Measures

With a focus on increasing the speed of innovation without sacrificing compliance, ION builds quality measures into every process. Rather than waiting to start traceability and diagnosing issues once supplier parts are in your supply chain, ION makes it possible to catch issues during inspection, right when they’re delivered. This proactive approach reduces rework time due to defective parts. Then, escalating issues back to Arena PLM closes the quality loop, allowing you to flow corrective actions back to design for continuous improvement.

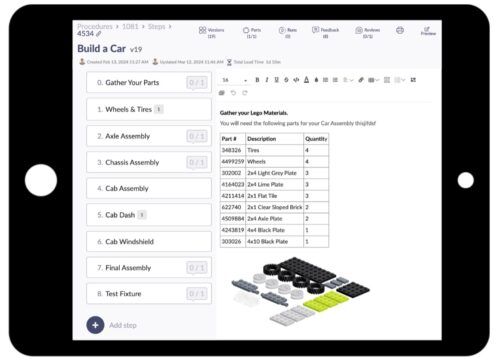

Agile Manufacturing: Streamlining Assembly With ION’s Visual Work Instructions

Using ION, manufacturing engineers are immediately empowered with knowledge about the specific tools and parts sourced internally or externally, along with what’s needed for product assembly. From there, they can create visual work instructions with milestones and checkpoints—leveraging the principles of Agile manufacturing—so that quality is monitored throughout the process.

ION Factory OS Work Instructions

During production, ION enables technicians to raise issues in real time, so that engineers can solve them right away. When parts are replaced or require an upgrade, the new information is fed directly back to Arena PLM, ensuring an accurate historical record of the entire product journey that can be tracked down to the most granular level of detail.

Integrations Benefits

Need to make a revision? Find all parts in that part’s work instructions and update them without disrupting production—in both your MES and PLM (without double entry), so your technicians are always working from the most updated instructions, and your design engineers are kept in the loop.

Unlocking Data Insights With Arena PLM and ION Factory OS Integration

By integrating Arena PLM and ION Factory OS, manufacturers get access to insights that provide both the opportunity to explore the data and to apply data science, which did not exist in previous eras when legacy systems were in place.

As Arena PLM and ION Factory OS exchange data back and forth, upstream and downstream coordination opens up new opportunities for continuous improvement.

ION Analytics Dashboard Example

ION’s dashboards provide out-of-the-box reporting and the ability to build custom data views. In just a few clicks, you get high-level visibility of the all-in cost of a build (aBOM) that reveals every part, labor hour, and technician involved, plus quality dashboards that monitor issues and point you to the root cause. ION makes it easy to uncover bottlenecks in your factory, along with dozens of other manufacturing metrics that come standard.

Learn more about the Arena PLM and First Resonance Integration.