Delivering Significant Business Value: Establish Metrics

In the previous blog post, we proposed that by adding significant value to your organization, you will be rewarded. After targeting a process, use metrics to justify your proposal to improve the process. Later on, you can use “Before and After” metrics to explain the value of your improvements. Taking these steps will help you establish your value in the company.

“You can’t improve what you can’t measure.” Old Business Adage[1]

Now, let’s measure the targeted process.

Establish Metrics

Establish metrics to communicate the potential value of your effort to justify your plans. Once you’ve improved the process, use these metrics to communicate your results. Let’s take another look at the OEM.

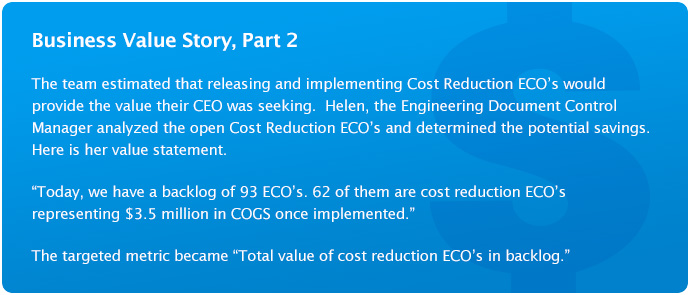

The Engineering Document Control Manager chose metrics that correlated with the CEO’s goals. Here are some other measurable results from improving product lifecycle management (PLM) processes that support corporate goals.

- Accelerating NPI to gain market share

- Reducing scrap and rework costs to improve profit margin

- Accelerating new feature releases to respond to customer feedback

- Reducing supplier quality issues to improve time to market, profit margin, and product quality

- Accelerating the prototype to pilot process to beat competition

- Reducing customer returns to improve repeat customers

Select a metric or a set of metrics that will resonate with management. When you present the potential value, be ready to explain how you calculated that number. Include estimates, assumptions and valid ranges to further your credibility.

An example estimate is: “Of the 62 cost reduction ECO’s in backlog, I took a sample 30. Tossing the outliers, the average savings estimated by the ECO originator was about $56,000 each. I took that number, multiplied it by the total to get $3.5 Million.”

An example estimate is: “Of the 62 cost reduction ECO’s in backlog, I took a sample 30. Tossing the outliers, the average savings estimated by the ECO originator was about $56,000 each. I took that number, multiplied it by the total to get $3.5 Million.”

An example assumption is: “I’m assuming all these ECOs can be implemented. I’m assuming they are all still opportunities; they haven’t been addressed by other changes. I rounded down on the average savings per ECO to make up for that.”

An example range is: “When we contract with the cost reduction engineer to implement these changes, the firm stated they will implement between 5 and 20 per week. Using a rate of 5.1 ECOs per week, we believe we can close these out in 3 months.”

Use these metrics to get approval for your project. The next step is to plan and execute the improvement. Knowing your metrics will help in this next step by giving you an idea of a reasonable investment.

Note: These are some best practices I’ve found. It’s not exhaustive. It’s meant to start a conversation. Comment with your response, your ideas and your experiences. If you email them to me, I can post them with a pseudonym or no name. Thank you!

[1] Side Diatribe: Are bloggers not counting visits? Not checking their Google ranking? This is why that saying persists! Some people are polarized by this saying, e.g. Blog post in Forbes by Liz Ryan . I’ll contend that as an Engineering Document Control Manager, you see the big picture. You are a professional who works with many people, processes, and regulations. I know that you:

- Measure processes,

- Figure out ways to improve them,

- Do not wreak havoc in other areas of the company to improve your target process.

I will also state that your salary

- Is measurable,

- Correlates with demonstrable value.

And, finally

- Measurably improved processes have immeasurable benefits as well. For example, “This new simpler process frees me up to do more valuable work.” Document these comments to strengthen your case.

- Aligning your value with upper management’s value puts you on the right track.