Sharing Product Record and BOM Information: Maximizing Value Between PLM and ERP

Today, more manufacturers understand the integration of product lifecycle management (PLM) and enterprise resource planning (ERP) solutions improves efficiency and quality of product development delivery; this is done by ensuring the bill of materials (BOM) data captured in the PLM system is available in real-time across the enterprise to internal and external supply chain teams.

The value of integrating ERP and PLM is an old story that we’ve written about plenty of times before. But many innovative product companies now ask whether they should use an ERP or PLM solution instead of investigating how to most effectively integrate the two solutions to fully realize the value in both.

What’s complicated this growing confusion whether to use ERP or PLM is that the capabilities of PLM solutions have become so comprehensive, mature, and wide-ranging, many manufacturers are baffled which of these two enterprise solutions is best designed to solve their specific manufacturing challenges. This perspective is validated by IDC analyst Joe Barkai, “We will see more and more PLM companies encroaching into what has traditionally been ERP territory.”

Seamless Integration of PLM and ERP Systems

Arena believes the true value of integration occurs when product development and execution processes are functions of PLM and ERP alike in a seamless, end-to-end solution. This integration links together the critical upstream and downstream processes and data between classically disparate user groups who work in different enterprise systems.

To achieve this goal, Arena’s API provides an ideal framework and integration environment between PLM and ERP for the release and bi-directional data sharing from one system to the other. This allows innovative product companies to streamline efficiencies for developing superior products.

The benefits of integrating ERP and PLM—and the impact that it has on a manufacturer’s success — can be expected to grow as ERP and PLM are further integrated to enable bi-directional data sharing.

Strategic Impact of PLM on ERP Efficiency and Business Processes

Gartner confirms this saying, “In addition to PLM’s inherent value, PLM decisions have a strong influence on the business model and benefits that can be realized by ERP, SCM and CRM applications in downstream business processes; in that sense, PLM is the most fundamental business application in manufacturing. Since PLM fundamentally defines bills of materials, it influences the efficiency of ERP and supply chain activities.” (Gartner Group, Inc. “PLM’s Business Value Is Fundamental, Yet Still Not Well Understood.”)

The difference between ERP and PLM is that ERP executes and optimizes manufacturing and distribution processes involving physical assets; however, ERP is less effective than PLM at managing product-specific design changes, including data from the product’s BOM.

PLM and ERP: Integrating Features Across the Product Lifecycle

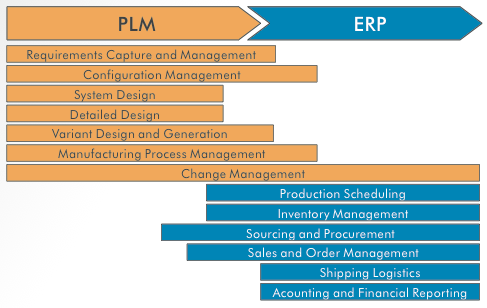

Another difference between PLM and ERP is that the PLM solution’s features and functionality are leveraged throughout the product lifecycle, from the design stages into the manufacturing process. A model ERP/PLM integration combines the capabilities of the PLM system to manage and update all engineering content and processes and all of a product’s BOM (or as-built Bill of Materials) with the ERP system’s management of the physical product.

SHARING PRODUCT RECORD AND BOM INFORMATION: MAXIMIZING VALUE BETWEEN PLM AND ERP

An example of a successful ERP and PLM integration is the high-profile success of Nextracker, one of the fastest-growing cleantech companies in solar tracking today. Looking to enhance product information management and streamline processes with distributed teams, Nextracker adopted Arena’s cloud-native PLM solution.

The cloud-native solution facilitated better collaboration and integration with design and ERP systems, including Oracle® NetSuite. Ratana Lee, Senior Manager, NPI Master Archivist appointed to lead PLM adoption, emphasized that using Arena for centralizing product data and automating design processes has boosted innovation and efficiency.

Expanding Global Efficiency with Arena’s Cloud-Native PLM Solution

Arena’s cloud-native PLM solution is extensively used by over 300 internal members and 200 supplier partners across five countries, improving daily operations and sourcing high-quality products rapidly. A key feature is its capability to push necessary product information to Oracle® NetSuite, supporting sales, purchase order and manufacturing processes, and ensuring information accuracy.

Arena PLM also aids Nextracker’s contract manufacturing partners in the U.S. and India by providing secure, instant access to critical information. Plus, Nextracker leverages Arena’s quality management features for creating quality records and inspection reports. They’ve also developed a mobile app linked to Arena, aiding field service teams in harsh environments, enhancing data collection, and early issue detection.