Manufacturing BOMs (MBOMS) Are Critical to Successfully Build Products

The devil is in the details and the details of your product is found in the manufacturing BOM

The bill of materials is the core of any high-tech electronics or medical device product. Having an accurate manufacturing bill of materials (MBOM) is important because it provides details on all the parts required to build a final product. Unlike an engineering bill of materials (EBOM) which is organized according to the design of a product, the manufacturing BOM is structured to support how a product is assembled. Without a good MBOM, your product is at risk of being built slowly, incorrectly, or not at all.

What is a manufacturing bill of materials?

The manufacturing bill of materials contains all the parts and assemblies required to build a complete and shippable product. This includes packaging materials, instructions, and guides. It also incorporates items that are used in the assembly process, like liquid adhesives. Both off-the-shelf (OTS) components and custom, made-to-specification (MTS) parts belong on a manufacturing bill of materials, as well as non-tangible items like software and firmware. Any item that can be found in the final finished good needs to be included at some level of the manufacturing BOM.

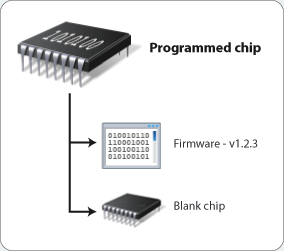

Some parts require processing—like pad printing, painting, or programming—before they are ready to be assembled into a final product. While only the altered part is assembled into the final product, both the pre-processed base part and the finished part are represented on the manufacturing BOM. The manufacturing team needs to know about all the processing steps in order to make critical decisions about which steps will be performed in-house and which will get outsourced to a separate vendor. The location of the processing may be changed during the life of the product to reduce costs, improve quality, or increase flexibility.

Only the programmed chip is in the final product, but the blank IC and the correct revision of firmware are needed to create the programmed chip. Manufacturing often changes the location of easily transferred processes like programming depending on the production lifecycle stage. For example, beta and early production units may be programmed in-house while mature products with stable software can be programmed at the electronics manufacturing services (EMS) vendor who supplies the PCBAs.

Only the programmed chip is in the final product, but the blank IC and the correct revision of firmware are needed to create the programmed chip. Manufacturing often changes the location of easily transferred processes like programming depending on the production lifecycle stage. For example, beta and early production units may be programmed in-house while mature products with stable software can be programmed at the electronics manufacturing services (EMS) vendor who supplies the PCBAs.

Why is the manufacturing BOM so important?

The bill of materials for manufacturing enables the final transition from a concept to a physical product. The more accurate and complete the contents of the manufacturing bill of materials are, the better the decisions you can make about how to get the product efficiently and cost-effectively into the customer’s hand.

How and where a part will be made impacts the purchasing of components and processed parts, the availability of inventory, and the contents of build kits on the manufacturing line. It determines what steps happen on the assembly floor during the production run and what happens ahead of time (possibly at another vendor). Options like these create trade-offs between time, money, and control, and those decisions need to be managed as part of the new product introduction (NPI) process. The accuracy and completeness of a manufacturing bill of materials allow a company to make better trade-offs and improve its ability to successfully plan, procured, build, test, ramp, and introduce a new product.

The manufacturing bill of materials drives manufacturing, operations, purchasing, and logistics for a product. The information from the MBOM feeds the business systems used to order parts and build the product. These include enterprise resource planning (ERP) and manufacturing execution system (MES) solutions.

Inaccuracies in a manufacturing BOM lead to problems: If the wrong parts or wrong quantities of parts are ordered, a company will not be able to build enough product—or any product at all. This leaves the company with unusable components that need to be returned or extra parts that tie up money in inventory. For manufacturing and operations teams that are already running lean, cleaning up these mistakes wastes time and money. Depending on the size of the original mistake, the amount of money lost could be large enough to significantly impact the company’s bottom line.

Intelligent BOM Management for Today’s Innovators

For product companies working with distributed teams and supply chain partners, collaborating on the latest bill of materials (BOM) is critical to reduce production errors and shipping delays. In this ebook, we identify the problems with traditional, manual approaches and explain why Arena provides a more intelligent and comprehensive way to control, share, and release accurate BOMs and related product information.

Bill of Materials (BOM) Management topics covered:

- BOM management challenges such as change, revision and compliance management

- Communication issues with project teams, suppliers and contract manufacturers

- Comparison of manual vs. automated BOM management tools

HOW DOES AN MBOM DIFFER FROM AN EBOM?

The major differences between the manufacturing bill of materials and the engineering bill of materials are in their structure and depth. Manufacturing BOMs must contain all the parts and assemblies. If an item needs to be purchased to make the final product, then it needs to be represented on the MBOM. All these parts are structured into the manufacturing bill of materials based on how the product is assembled. For instance, if a product has ten 6-32 screws, each screw is listed in the manufacturing BOM in the subassembly where it is used. On the other hand, the engineering BOM for this product may only have one line item that lists the 6-32 screw with a quantity of 10. The engineering BOM may not provide any information about how parts relate to each other.

In fact, there may be more than one engineering BOM because different engineering departments each create their own. The structure of the mechanical BOM is generally derived from the mechanical CAD model. That BOM is organized according to the engineers’ design process and often contains groups of unassociated parts collected together for the engineers’ convenience in working with the model. Mechanical BOMs commonly list printed circuit board assemblies (PCBAs) as a single item because adding hundreds of tiny components is tedious, slows work on the CAD model, and adds little value to the mechanical design process. Electrical BOMs, on the other hand, only show all the components that make up the PCBAs; they don’t deal with the rest of the product at all. And the firmware required for a product may not be listed on either the mechanical or the electrical BOM.

The Detailed Complexity of Manufacturing BOMs vs. Engineering BOMs

In addition to being more complete, MBOMs tend to have more levels to describe each stage of the assembly process in more detail. For example, the lens subassembly that needs time to cure will be called out separately with its own part number and manufacturing work instructions (MWI). In the EBOM, the individual lenses and mounts would exist, but they would be included in a larger optical assembly. For the mechanical engineers, the many subassemblies needed by manufacturing add layers of complexity to the structure and make it harder to work with the CAD model.

Manufacturing BOM vs. Engineering BOM

MBOM

- Organized into subassemblies that reflect the manufacturing process

- Represents the physical product, packaging and included documentation

- Contains all components required to build the product—MTS, OTS, mechanical, electrical, software & firmware

EBOM

- Organized according to MCAD/EDA tools

- Represents the physical product being “engineered,” not the packaging or manufacturing consumables

- Often includes items for a single engineering discipline only, summarizing or excluding items from other disciplines

Is Your Part Numbering Scheme Costing You Millions?

Manufacturers of complicated electronic products must manage, track, and store hundreds—if not thousands—of parts in their product development processes. And every time a new part is added to a company’s library, it can cost $15k in time and effort to qualify and rollout.

That’s serious money.

And that’s why choosing the proper part numbering scheme to reference your parts is critical to your manufacturing business’s success.

In Arena’s “Part Numbering ebook,” you’ll learn how to choose the best part numbering scheme for your business.

- Pros and Cons of Intelligent & Non-Intelligent Part Numbering

- Considerations for Choosing Your Part Numbering Scheme

- Part Numbers in Your Business

- How Arena Handles Part Number with Real-World Examples

In fifteen years of working with manufacturers of all sizes, Arena has developed deep insights into the different approaches and best practices of part numbering. These findings can be yours. Download the Part Numbering ebook today.

Better BOMs enable better decisions

A detailed bill of materials is critical to the successful management of manufacturing resources. With an accurate BOM, the new product introduction process is smoother, and the ramp to full production is more controlled. With knowledge about ALL components and steps in the manufacturing process, the operations team can make appropriate trade-offs throughout the life of a product. Arena’s PLM and QMS solutions are simplified with Arena’s cloud-based bill of materials software. To learn more check out our free BOM template in Excel or PDF format.