Air International Thermal Systems is a global Tier-1 supplier of heating/ventilation/air conditioning (HVAC), seat systems, steering systems, metal pressings, fabrication, modular assemblies, and rail and bus HVAC systems to the world’s automotive industry. With divisions in Australia, North America, China, Thailand, Europe, and India, Air International (AI) has thousands of employees along with twenty-one locations and technical centers that service automotive companies with customers that include Ford, Jaguar, General Motors, and Volkswagen.

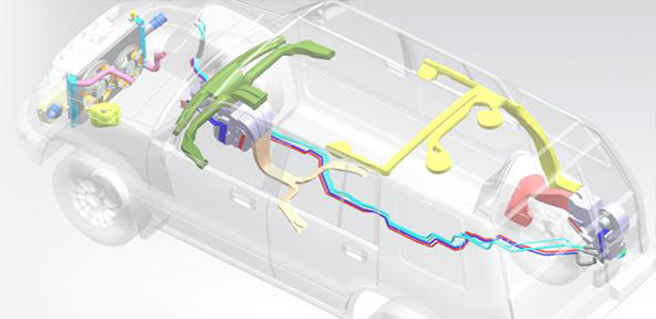

To provide outstanding comfort for drivers and passengers

Since 1996, the company has used an outsourced manufacturing strategy instead of maintaining its own manufacturing facilities. With no manufacturing plants in North America, Air International depends on its supply chain to provide a less expensive, high-quality product faster than its much larger competitors. This outsourcing strategy provides Air International with a number of key benefits, including lower overhead costs, the ability to find the best technology for the lowest price, and the flexibility to select the right contract manufacturer.

For the first several years, communication between Air International and its outsourced partners was based on traditional, manual processes. Bids were developed on paper or spreadsheets and spawned the seemingly never-ending rounds of follow-up questions and emails. Collaborating with multiple copies and versions of supporting documents was error-prone and tedious to track. As a result, AI could only obtain a limited number of quotes for any new project and had difficulty ensuring it was always taking advantage of the best quote available. AI believed this increasingly complex manual communication was forming a barrier that was preventing the company from maximizing the benefits of its contract manufacturing strategy.

“Lacking the ability to afford a cost-prohibitive on-premises product lifecycle management system, AI did the best it could with spreadsheets, emails, and FTP sites. “We had to rely on hand-delivery or sending documents overnight,” said Michael Repetto, General Manager at Air International.

During this time, AI began investigating product lifecycle management (PLM) solutions to see if they could improve the outsourcing process, noting: “With teams working around the clock and around the globe, we were spending too much time on administrative overhead and we still couldn’t ensure that everyone in our network always had access to the latest information.”

AI briefly considered on-premises PLM systems. However, those systems were very expensive to install, required heavy IT resources, and weren’t designed for secure real-time collaboration between external partners and globally dispersed employees. Worse yet, they required months to deploy as opposed to weeks for a cloud-based system.

– Michael Repetto, General Manager, Air International Thermal Systems

After ruling out on-premises PLM solutions, Repetto led an evaluation of cloud-based solutions. Arena was selected based on these advantages:

After ruling out on-premises PLM solutions, Repetto led an evaluation of cloud-based solutions. Arena was selected based on these advantages:

After purchasing a subscription for Arena PLM, AI’s PLM workspace was immediately activated. Then Air International simply imported its product information, set up the administrative functions, and configured access for key suppliers and manufacturers. In less than a week, AI’s teams were exploring the full Arena PLM solution and sharing the latest BOMs with their contract manufacturers. “Going with Arena PLM was essentially a no-risk proposition,” says Repetto. “With no large upfront costs and a pay-as-you-go subscription model, we could evaluate the full system with our own data and be confident that it would work in our environment before making an ongoing investment. The ability to simultaneously mitigate our risk and rapidly deploy a new system was critical in our increasingly competitive market with contracting margins and shrinking product development cycles.”

After ruling out on-premises PLM solutions, Repetto led an evaluation of cloud-based solutions. Arena was selected based on these advantages:

After purchasing a subscription for Arena PLM, AI’s PLM workspace was immediately activated. Then Air International simply imported its product information, set up the administrative functions, and configured access for key suppliers and manufacturers. In less than a week, AI’s teams were exploring the full Arena PLM solution and sharing the latest BOMs with their contract manufacturers. “Going with Arena PLM was essentially a no-risk proposition,” says Repetto. “With no large upfront costs and a pay-as-you-go subscription model, we could evaluate the full system with our own data and be confident that it would work in our environment before making an ongoing investment. The ability to simultaneously mitigate our risk and rapidly deploy a new system was critical in our increasingly competitive market with contracting margins and shrinking product development cycles.”

Beyond the lower price and IT-related support costs associated with Arena PLM—the logistics of deploying the system across a large supply chain was a big benefit. “With Arena’s cloud-based solution, there’s no need to deploy software onsite for suppliers, and the cost of adding suppliers is a fraction of the on-premises providers,” says Repetto. “Air International collaborates with hundreds of suppliers using Arena, a feat which would prove far too expensive and unwieldy with traditional PLM software.”

AI saves 10 percent on its parts cost with Arena PLM because of “greater visibility into their supplier’s costs.” This has allowed AI to cut its own prices by 10 percent to stay competitive with its larger Tier-1 competitors.

Arena PLM has also been leveraged to optimize the prototyping process. “Making an incorrect prototype assembly can easily waste more than $10,000,” says Repetto, “and since the prototypes can take weeks to build, precious time is also wasted, introducing delays that can cascade throughout the schedule.”

“Having a ‘single version of the truth’ that all suppliers can follow has eliminated mistakes due to miscommunication or the use of out-of-date documents,” says Repetto. “When an engineering change order is created, all relevant suppliers are notified immediately and the documents are readily available.”

During production, AI uses Arena PLM to ensure suppliers are making the right part to the correct revision level. This aspect is critical, Repetto says, “because mistakes made at this stage could require us to go directly to the automotive OEM assembly plant to replace incorrect products and incur substantial sorting costs, expediting costs, and penalties.” Using Arena PLM, all suppliers and manufacturing sites have access to current drawings and CAD data, he adds. “In the event an issue arises, they can quickly find and download the relevant data to compare to the product, which results in faster resolution of issues.”

Arena has strengthened the bonds of AI’s supply chain for maximum business impact. Beyond prototyping and production issues, managing large and global chains can be challenging. After all, established suppliers can go out of business, change focus, or even get dropped due to substandard quality or delivery issues.

When AI needs to get quotes from new suppliers, they can add prospective suppliers to Arena PLM, which enables them to share all of their drawings, CAD files, specifications, and other documents, Repetto says. “All information is completely current and everyone has access to the same information—making the quoting process much more efficient. It eliminates the traditional problem of global version control.”

Arena PLM makes the process easier for new suppliers. “For instance, if a potential new supplier is interested in selling to Air International, once we send the supplier an invitation, sales reps can upload a virtual tour of their facility, presentations, and data sheets that give us a complete picture of their capabilities,” says Repetto. “We can source from suppliers all over the world, which enables us to access much lower pricing through increased competition.” This streamlined process has enabled AI to reduce the amount of time it takes to procure supplier quotations by 20%.

– Michael Repetto, General Manager, Air International Thermal Systems